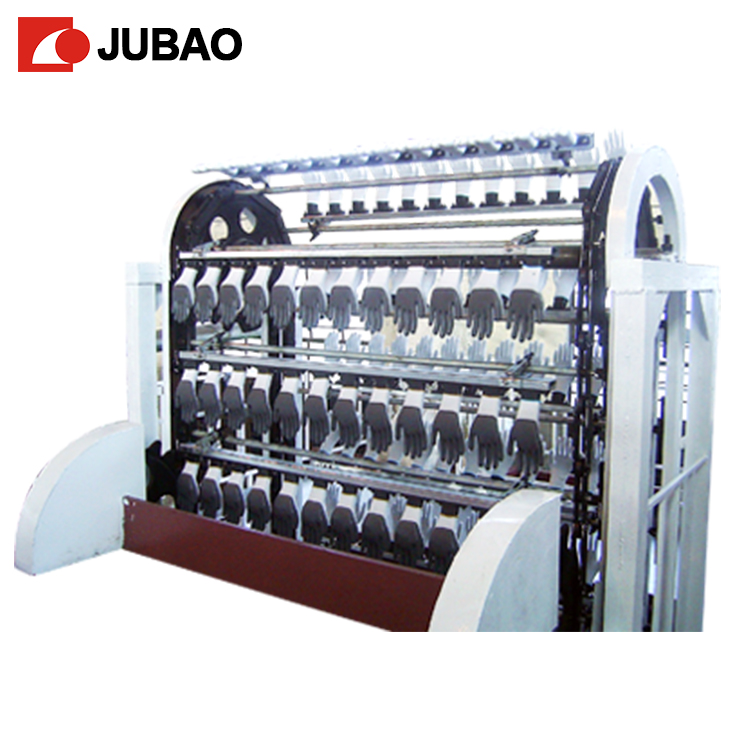

JUBAO High-Efficiency Nitrile Glove Dipping Machine - Automated Solution for Mass Production

PRODUCT SERIES: Glove Machine Seires

Color:

-

JUBAO TECHNICAL MACHINE LIMITED introduces the High-Efficiency Nitrile Glove Dipping Machine, designed to transform your glove manufacturing process. This automated system supports a range of materials including latex, nitrile, NBR, PU, and PVC. With cutting-edge technology, the machine optimizes production flow, minimizes material wastage, and delivers consistently high-quality gloves, ideal for industries looking to streamline and scale operations.

Core Features:

- High-Capacity Continuous Operation: The continuous chain system drives non-stop production, significantly increasing output while maintaining efficiency.

- Precision Dipping Control: The system ensures the dipping depth and length are automatically regulated, resulting in uniform glove thickness and reliable quality.

- Compact and Space-Efficient: Tightly arranged molds save valuable oven space, reducing the overall machine footprint and improving energy utilization.

- Advanced Airflow System: The hot air circulation system is designed to evenly distribute heat throughout the oven, ensuring consistent glove curing and reducing product variability.

- Waste Reduction Technology: The latex collection and recycling system captures excess material, allowing for reuse and lowering material costs.

- Streamlined Mold Change: The machine allows for easy mold changes by replacing entire rows of molds simultaneously, keeping production disruptions to a minimum.

Technical Specifications:

Model/length

JB-SUB6A

JB-SUB6B

JB-SUB8

JB-SUB10

JB-SUB12

Dimension(m)

12

18

30

30

30

Capability(pairs/hr)

500

1800

3400

4300

5200

Power(kw)

4.5

5.5

6.5

7

7.5

Mold(pairs)

420

886

1200

1500

1800

Heat consumption(kcal/hr)

160000

200000

300000

400000

500000

Why JUBAO TECHNICAL MACHINE LIMITED?

JUBAO TECHNICAL MACHINE LIMITED is dedicated to providing manufacturers with the most advanced and efficient solutions for glove production. Our High-Efficiency Nitrile Glove Dipping Machine is a testament to our commitment to innovation, productivity, and sustainability. By integrating this system into your production line, you ensure not only a boost in output but also a reduction in operational costs and waste. -

Model/length

JB-SUB6A

JB-SUB6B

JB-SUB8

JB-SUB10

JB-SUB12

Dimension(m)

12

18

30

30

30

Capability(pairs/hr)

500

1800

3400

4300

5200

Power(kw)

4.5

5.5

6.5

7

7.5

Mold(pairs)

420

886

1200

1500

1800

Heat consumption(kcal/hr)

160000

200000

300000

400000

500000