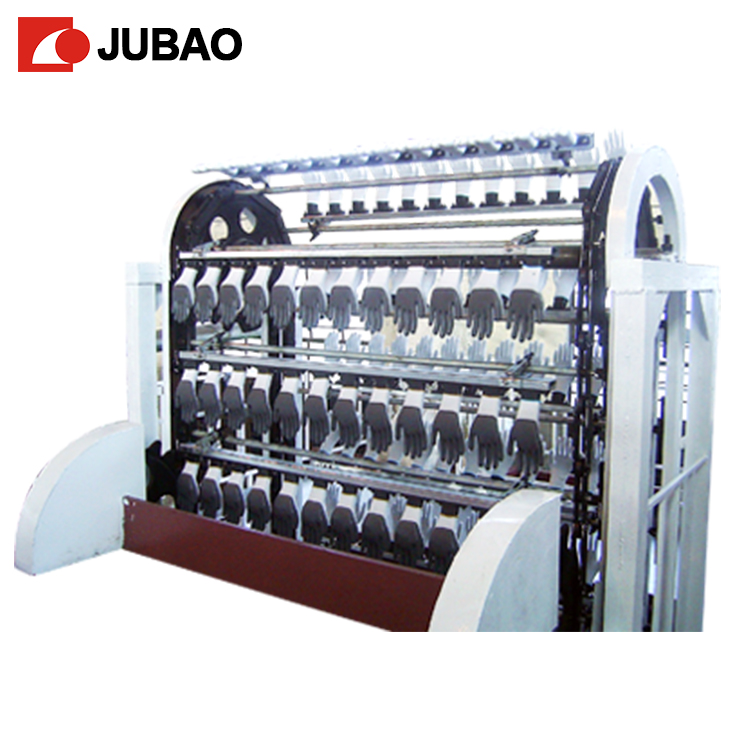

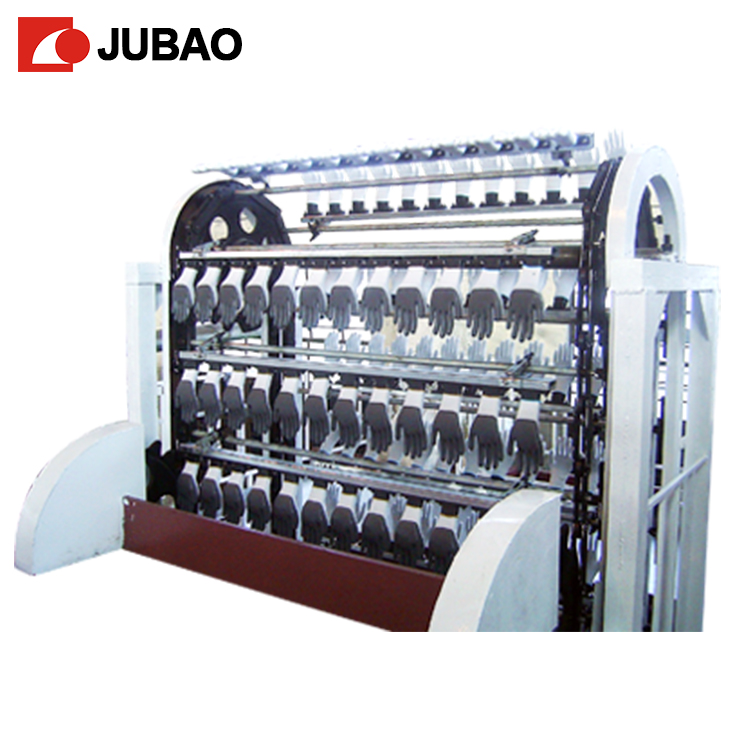

JB-SUC Advanced Glove Dipping Machine for Precision Manufacturing

PRODUCT SERIES: Glove Machine Seires

The JB-SUC Advanced Glove Dipping Machine from JUBAO TECHNICAL MACHINE LIMITED is designed to meet the needs of glove manufacturers who demand precision, efficiency, and high production quality. This cutting-edge system is tailored for producing top-tier gloves, ensuring superior material application and consistency.

Color:

-

Key Features:

- Multi-Material Compatibility: Designed to work with various glove materials such as latex, nitrile, NBR, PU, and PVC, the JB-SUC delivers exceptional versatility, making it suitable for producing a wide range of glove types for different industries.

- Hydraulic Dipping System: The machine incorporates an advanced hydraulic lifting system that allows for precise control over the dipping angle. This ensures consistent coating across every glove, minimizing defects and enhancing overall production quality.

- 360-Degree Material Distribution: Equipped with an innovative 360-degree chain rotation mechanism, the JB-SUC ensures uniform material distribution during the dipping process. This results in a smooth, high-quality finish on every glove, elevating product aesthetics and durability.

- Advanced Coagulant and Wrinkle Prevention: The JB-SUC also features a unique coagulant application system that enhances the quality of the dipped gloves. Its wrinkle prevention capability ensures a smoother surface, perfect for high-end glove manufacturing.

Technical Specifications:

- Model Variants: Available in four models—JB-SUC6, JB-SUC8, JB-SUC10, and JB-SUC12—each designed to cater to different production scales.

- Standard Machine Length: All models have a uniform length of 30 meters, providing a compact yet efficient production line setup.

- Production Capacity: The JB-SUC6 model starts at 520 pairs per hour, while the largest model, JB-SUC12, reaches up to 5,200 pairs per hour, ensuring scalability for growing production needs.

- Power Efficiency: Power consumption ranges from 6 kW to 7.5 kW, depending on the model, making the JB-SUC an energy-efficient choice for manufacturers.

- Mold Capacity: The machine supports between 675 pairs for JB-SUC6 and up to 1,350 pairs for JB-SUC12, allowing for larger batch production without compromising on quality.

- Optimized Heat Usage: Heat consumption is carefully controlled, with requirements between 160,000 kcal/hr to 500,000 kcal/hr, ensuring efficient energy use and cost-effective production.

With its innovative features and robust construction, the JB-SUC Advanced Glove Dipping Machine is the perfect solution for manufacturers looking to enhance their glove production capabilities. Designed by JUBAO TECHNICAL MACHINE LIMITED, this machine combines reliability, efficiency, and cutting-edge technology to deliver exceptional results. Whether you’re producing gloves for industrial, medical, or personal use, the JB-SUC ensures a flawless finish and consistent quality in every production cycle.