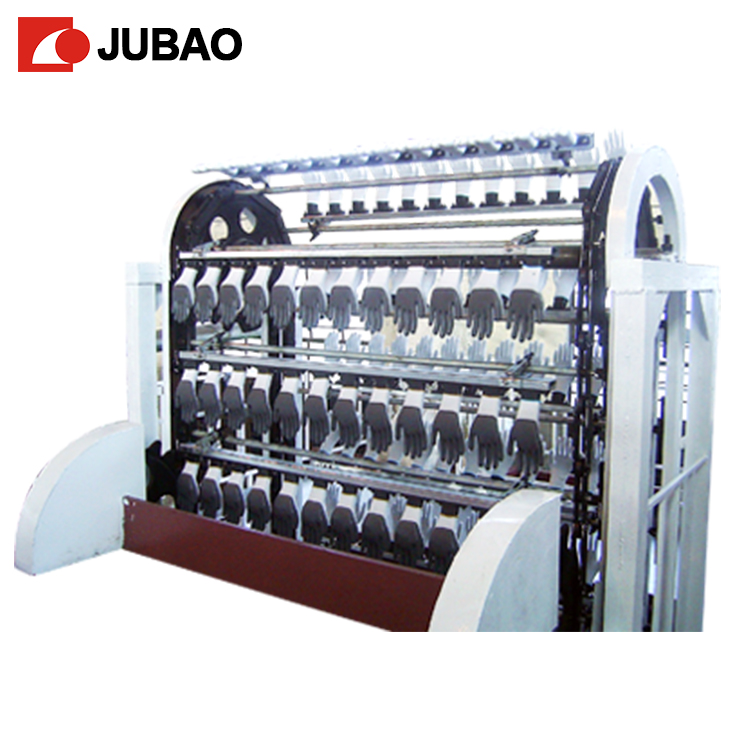

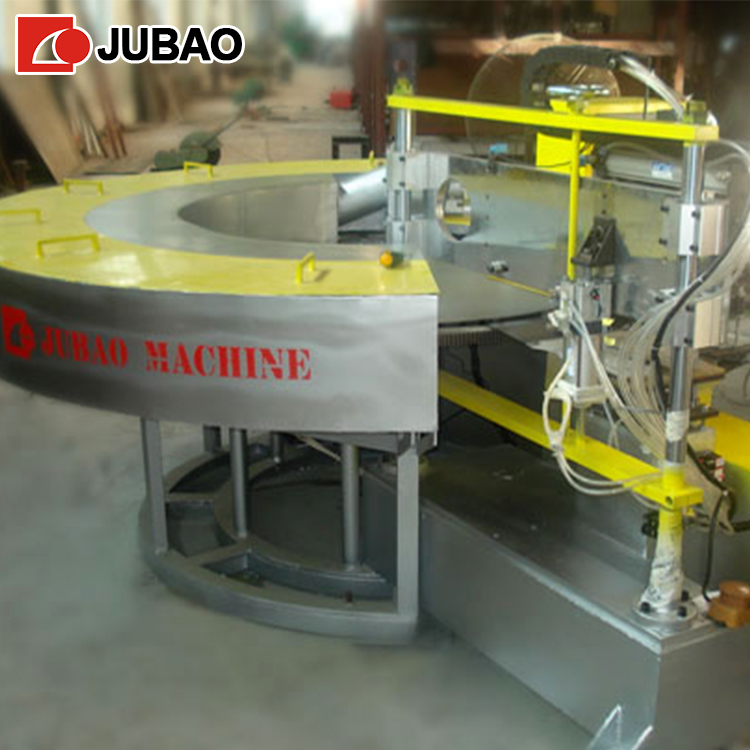

JB-SDB High-Performance PVC Glove Dotting and Printing Machine

PRODUCT SERIES: Glove Machine Seires

The JB-SDB High-Performance PVC Glove Dotting and Printing Machine, manufactured by JUBAO TECHNICAL MACHINE LIMITED, is designed to elevate glove production by providing precise dotting and printing on various glove materials. This state-of-the-art machine is suitable for producing industrial gloves, especially those requiring enhanced grip and durability. Ideal for manufacturers seeking to improve their production efficiency, the JB-SDB offers top-tier performance with consistent quality output for industries like construction, manufacturing, and safety equipment.

Color:

-

Key Features:

- Versatile Material Compatibility: The JB-SDB supports a wide range of materials, including PVC emulsion, silicon (SN5200), latex, and vinyl, making it versatile enough to produce gloves for various applications. Whether for industrial use, medical settings, or protective workwear, the machine ensures that each material performs to its full potential.

- Accurate Dotting and Printing: The advanced dotting and printing technology guarantees precision in applying patterns or dots on gloves. This not only enhances the glove’s grip but also improves the wear resistance and overall durability, making the product suitable for challenging work environments.

- Efficient Production Capacity: Capable of producing 60 dozen pairs of gloves per hour, the JB-SDB is designed to maximize productivity. Its optimized hand mold system allows for efficient material handling while ensuring consistent product quality throughout the manufacturing process.

- Temperature-Controlled Oven: The machine features a built-in oven with a maximum temperature of 300°C, ensuring proper curing and finishing of gloves. The controlled temperature environment preserves the integrity of the gloves while preventing overheating, resulting in longer-lasting and safer products.

- Energy-Saving Operation: With an energy-efficient power consumption system, the JB-SDB requires 12 kW during start-up and drops to 6 kW during normal operation. This energy-saving feature ensures that production costs remain low without compromising on productivity or quality.

- Compact and Durable Design: The machine’s compact dimensions allow for easy integration into various production setups, while its robust build ensures long-term durability and minimal maintenance requirements, helping manufacturers save on operational costs over time.

- User-Friendly Interface: Designed with simplicity in mind, the JB-SDB comes with an intuitive control system that makes it easy for operators to manage and adjust the machine's settings, ensuring smooth and efficient operations even with minimal training.

Technical Specifications:

- Model: JB-SDB

- Machine Dimensions: 2.9m (L) x 2.6m (W) x 1.5m (H)

- Oven Temperature Range: Max 300°C

- Hand Mold Capacity: 17 pairs per cycle

- Air Pressure Requirement: 0.4 mpa

- Air Consumption: 1.1 cbm/min

- Power Consumption: Start-up: 12 kW; Normal Operation: 6 kW

- Power Supply: 3-phase, 380V, 50Hz

- Production Capacity: 60 dozen pairs of gloves per hour

- Weight: 700 kg

The JB-SDB High-Performance PVC Glove Dotting and Printing Machine is the perfect solution for glove manufacturers looking to enhance their production capabilities. With its advanced technology, efficient energy use, and ability to handle multiple materials, this machine ensures that each glove produced meets the highest standards of quality and durability. Designed for long-term use, it offers both productivity and reliability, making it a valuable asset to any glove manufacturing operation.