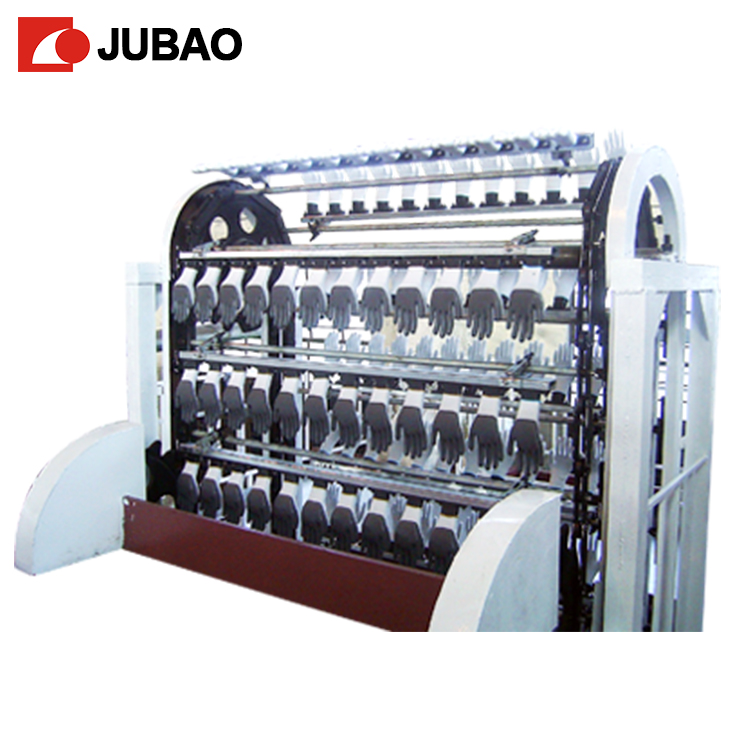

JUBAO Advanced Nitrile Glove Dipping System - Precision Engineering for Maximum Output

PRODUCT SERIES: Glove Machine Seires

Color:

-

Introducing the JUBAO Advanced Nitrile Glove Dipping System, a cutting-edge solution for producing high-quality gloves with maximum efficiency. Engineered for precision, this machine supports a wide range of materials, including latex, nitrile, NBR, PU, and PVC. With intelligent design features that boost productivity while reducing costs, it's the ideal choice for manufacturers looking to scale their operations.

Detailed Features:

- High-Speed Production Line: Built with a continuous chain system, the JUBAO dipping machine ensures rapid, high-volume glove production without compromising on quality.

- Automated Dipping Control: This system maintains consistent dipping levels and adjusts automatically, optimizing the production process for a uniform finish.

- Compact, Space-Saving Design: Molds are tightly arranged to maximize oven space, allowing for a smaller machine footprint while improving heat distribution.

- Advanced Temperature Regulation: The hot air circulation system ensures that heat is evenly distributed throughout the oven, creating ideal conditions for the curing process.

- Latex Recovery for Cost Efficiency: The integrated collection system recycles excess latex, reducing waste and driving down material costs.

- Quick Mold Change System: Easily replace entire rows of molds with minimal disruption to production, increasing operational uptime and efficiency.

Technical Specifications:

Model/length

JB-SUB6A

JB-SUB6B

JB-SUB8

JB-SUB10

JB-SUB12

Dimension(m)

12

18

30

30

30

Capability(pairs/hr)

500

1800

3400

4300

5200

Power(kw)

4.5

5.5

6.5

7

7.5

Mold(pairs)

420

886

1200

1500

1800

Heat consumption(kcal/hr)

160000

200000

300000

400000

500000

Why JUBAO?

At JUBAO TECHNICAL MACHINE LIMITED, we specialize in providing highly efficient, precision-engineered machinery designed to drive your business forward. Our glove dipping systems are built with innovation in mind, allowing you to produce more while minimizing costs. Whether you’re producing gloves for medical, industrial, or personal use, our machines offer the flexibility, speed, and durability you need to succeed. -

Model/length

JB-SUB6A

JB-SUB6B

JB-SUB8

JB-SUB10

JB-SUB12

Dimension(m)

12

18

30

30

30

Capability(pairs/hr)

500

1800

3400

4300

5200

Power(kw)

4.5

5.5

6.5

7

7.5

Mold(pairs)

420

886

1200

1500

1800

Heat consumption(kcal/hr)

160000

200000

300000

400000

500000