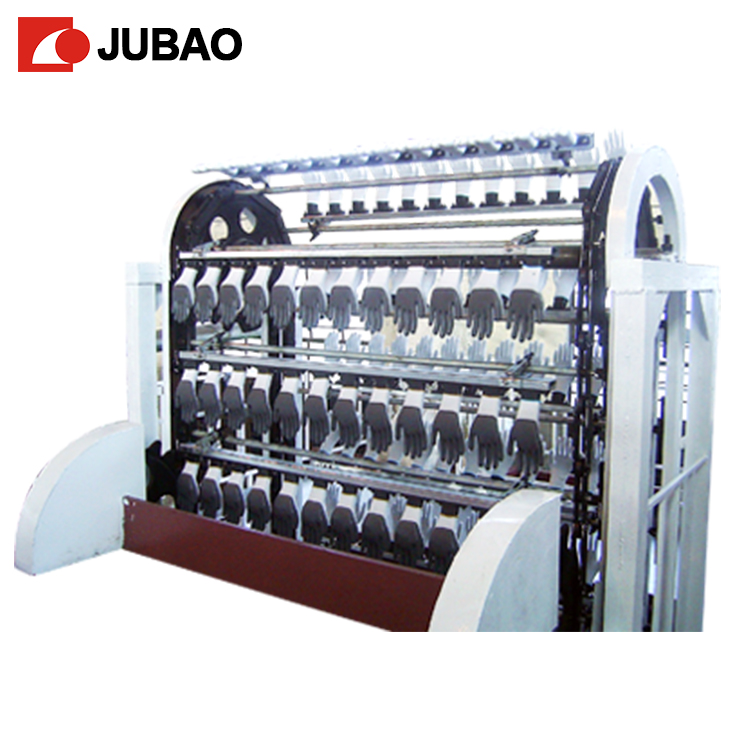

JB-SU Advanced Nitrile Latex PVC Glove Coating and Dipping Machine with 360 Rotation

PRODUCT SERIES: Glove Machine Seires

JUBAO TECHNICAL MACHINE LIMITED proudly presents the JB-SU Advanced Nitrile Latex PVC Glove Coating and Dipping Machine. This cutting-edge equipment is designed to handle a wide range of materials, including latex, nitrile, NBR, PU, and PVC, offering unparalleled versatility and efficiency. Incorporating the best features of the JB-SUB and SUC models, the JB-SU also introduces a 360° rotation function for precise and adaptable dipping angles.

Color:

-

Product Details:

- Material Compatibility: Engineered to process latex, nitrile, NBR, PU, and PVC, catering to diverse glove manufacturing requirements.

- 360° Rotation Function: This innovative feature allows for easy adjustment of dipping angles, facilitating finger dipping as well as 50%, 70%, and 100% dipping. This versatility minimizes the need for multiple mold styles, enabling the simultaneous production of various glove types and significantly reducing production costs.

- Premium Quality Production: Designed to manufacture gloves of the highest quality, ensuring superior performance and durability for medical, industrial, and other applications.

Product Attributes:

- Materials: Latex, Nitrile, NBR, PU, PVC

- Key Features:

- Combines the advantages of JB-SUB and SUC models

- 360° rotation for customizable dipping angles

- Flexible dipping options: finger dipping, 50%, 70%, and 100%

- Cost-effective production by reducing mold variety

- High-Quality Output: Guarantees the production of top-tier gloves suitable for a wide range of uses

Upgrade your glove manufacturing process with the JB-SU Advanced Nitrile Latex PVC Glove Coating and Dipping Machine, delivering flexibility, efficiency, and unmatched quality.

Finished products:

Tip: There is a need for more detailed information, please call customer service!

-

Technical information:

Model/length

JB-SUD8*18

JB-SUD8*30

JB-SUD8*50

JB-SUD10*50

JB-SUD12*60

Length(m)

18

18

30

50

60

Row(pcs)

8

8

8

10

12

Capability(pairs/hr)

684-720

1152-1440

1536-1920

1920-2300

2400-2880

Power(kw)

26

30

32

32

32

Mold(pairs)

860

1496

2552

3190

4224

Heat consumption(kcal/hr)

210000

340000

560000

620000

840000