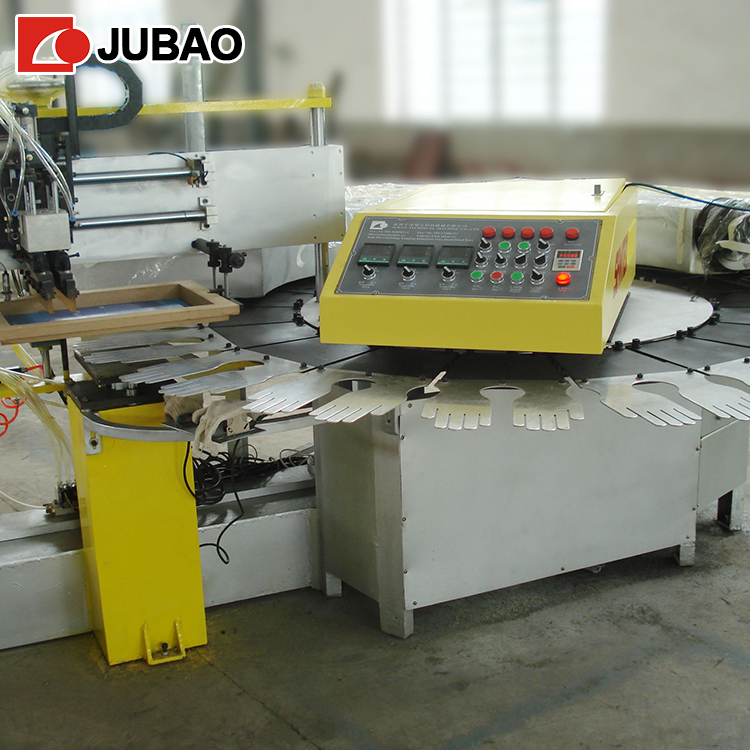

JB-SDB Precision PVC Glove Dotting and Printing System

PRODUCT SERIES: Glove Machine Seires

The JB-SDB Precision PVC Glove Dotting and Printing System, developed by JUBAO TECHNICAL MACHINE LIMITED, is an advanced solution tailored for industrial glove manufacturers who demand precision, efficiency, and versatility in their production processes. This cutting-edge machine is designed to apply dotting and printing patterns on gloves made from a variety of materials, enhancing the gloves' grip and wear resistance, making them ideal for industrial and safety applications.

Color:

-

Key Features:

- Multi-Material Compatibility: The JB-SDB system is capable of handling a broad range of glove materials such as PVC emulsion, silicon (SN5200), latex, and vinyl. This versatility ensures that manufacturers can cater to diverse market needs, producing gloves suitable for industrial, medical, and consumer use.

- Precision Dotting and Printing: The machine is engineered to provide high-precision dotting and printing on gloves, ensuring even and consistent application. This not only improves the appearance of the gloves but also significantly enhances their functional grip, making them ideal for heavy-duty applications.

- High-Efficiency Production: Designed for high-output environments, the JB-SDB can produce up to 60 dozen pairs of gloves per hour. The machine’s optimized workflow and 17-pair hand mold capacity ensure a smooth production cycle with minimal downtime, allowing manufacturers to meet high-demand orders with ease.

- Advanced Temperature Control: Equipped with an oven that can reach temperatures up to 300°C, the JB-SDB system ensures the proper curing of the gloves for enhanced durability. The precision temperature control mechanism allows manufacturers to adjust settings based on material requirements, ensuring consistent quality.

- Energy-Efficient Operations: The machine is designed with an energy-conscious approach, requiring 12 kW of power during start-up and only 6 kW during normal operations. This energy-saving feature helps reduce operational costs while maintaining high productivity and performance standards.

- Compact and Robust Design: Measuring 2.9m in length, 2.6m in width, and 1.5m in height, the JB-SDB is compact yet robust. Its durable construction ensures long-term, reliable operation, and its size allows for easy integration into various manufacturing setups without taking up excessive floor space.

- User-Friendly Control System: Featuring an intuitive control panel, the JB-SDB allows operators to easily manage production settings. With minimal training, operators can efficiently control the machine’s parameters, reducing the learning curve and ensuring a seamless production process.

- Air Pressure and Consumption Efficiency: The JB-SDB system requires a source air pressure of 0.4 mpa and has an air consumption rate of 1.1 cbm/min, ensuring efficient use of resources while maintaining consistent performance across each production cycle.

Technical Specifications:

- Model: JB-SDB

- Machine Dimensions: 2.9m (L) x 2.6m (W) x 1.5m (H)

- Oven Temperature Range: Up to 300°C

- Hand Mold Capacity: 17 pairs

- Air Pressure Requirement: 0.4 mpa

- Air Consumption: 1.1 cbm/min

- Power Consumption: Start-up: 12 kW; Normal Operation: 6 kW

- Power Supply: 3-phase, 380V, 50Hz

- Production Capacity: 60 dozen pairs of gloves per hour

- Weight: 700 kg

The JB-SDB Precision PVC Glove Dotting and Printing System is the perfect choice for glove manufacturers aiming to enhance both quality and efficiency in their production lines. With its ability to process multiple materials, precision in dotting and printing, and energy-efficient design, this machine is a comprehensive solution for producing gloves that meet the highest industry standards. Whether for industrial, medical, or commercial use, the JB-SDB delivers reliability, durability, and consistent output.