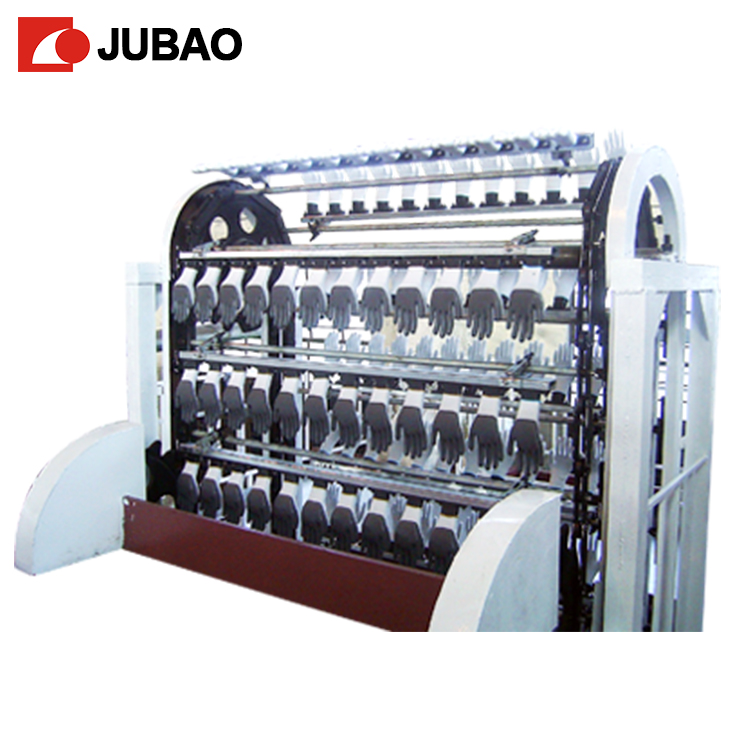

Automatic Nitrile Glove Dipping Machine - High Efficiency Production Line

PRODUCT SERIES: Glove Machine Seires

Color:

-

JUBAO TECHNICAL MACHINE LIMITED presents the Automatic Nitrile Glove Dipping Machine, engineered for high-capacity production of latex, nitrile, NBR, PU, and PVC gloves. Designed to optimize efficiency and reduce operational costs, this advanced dipping machine ensures consistent glove quality while minimizing waste. Ideal for manufacturers seeking reliable, high-output solutions for disposable glove production.

Product Features:

- Continuous Moving Chain: The machine utilizes a continuous moving chain system, enhancing production capacity while keeping costs low.

- Automatic Dipping Control: It maintains a balanced dipping level and automatically adjusts the dipping length, ensuring uniform glove quality.

- Space-Efficient Design: Compact mold arrangement maximizes oven space, reducing overall footprint and improving energy efficiency.

- Hot Air Circulation System: A state-of-the-art hot air cycle system ensures even temperature distribution within the oven, enhancing the curing process.

- Latex Recovery System: The machine is equipped with a collection system that allows for the reuse of excess latex, minimizing material waste.

- Easy Mold Replacement: Entire rows of molds can be replaced quickly and efficiently without impacting production capacity, simplifying maintenance and reducing downtime.

Technical Information:

Model/length

JB-SUB6A

JB-SUB6B

JB-SUB8

JB-SUB10

JB-SUB12

Dimension(m)

12

18

30

30

30

Capability(pairs/hr)

500

1800

3400

4300

5200

Power(kw)

4.5

5.5

6.5

7

7.5

Mold(pairs)

420

886

1200

1500

1800

Heat consumption(kcal/hr)

160000

200000

300000

400000

500000

Why Choose JUBAO TECHNICAL MACHINE LIMITED?

With a commitment to quality and innovation, JUBAO TECHNICAL MACHINE LIMITED provides state-of-the-art machinery tailored to meet the growing demands of glove manufacturers worldwide. Our machines are designed to optimize production efficiency, reduce costs, and ensure consistent product quality, making us a trusted partner in the industry. -

Model/length

JB-SUB6A

JB-SUB6B

JB-SUB8

JB-SUB10

JB-SUB12

Dimension(m)

12

18

30

30

30

Capability(pairs/hr)

500

1800

3400

4300

5200

Power(kw)

4.5

5.5

6.5

7

7.5

Mold(pairs)

420

886

1200

1500

1800

Heat consumption(kcal/hr)

160000

200000

300000

400000

500000