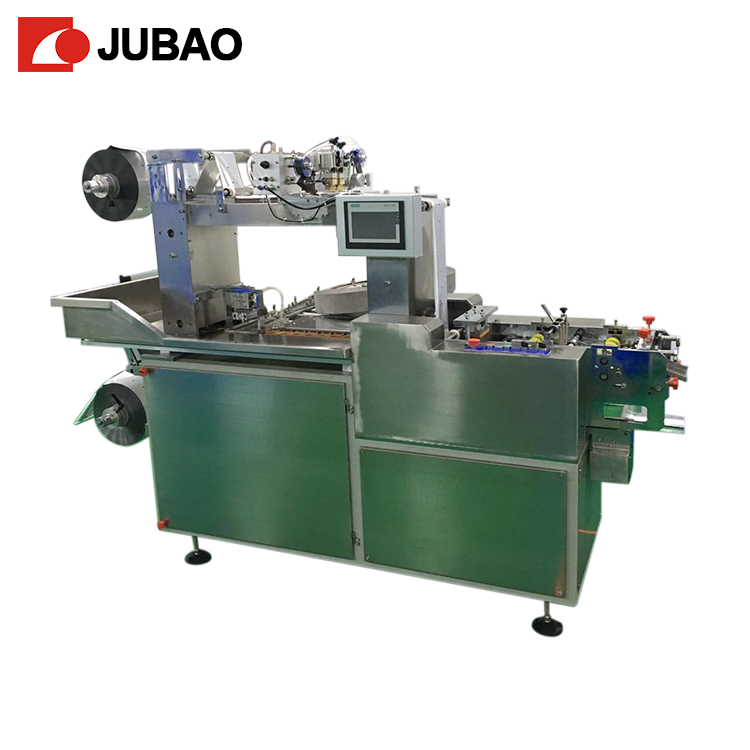

JB-DCT Dry Electronic Condom Testing Machine

PRODUCT SERIES: Condom Machine Series

1 | Machine size | 7.3m×1.7m×2.3m |

2 | Powder | 6KW |

3 | Mold pitch | 152.4mm |

4 | Max chain speed | 18m/min |

5 | Mold quantity | 208只 |

6 | Speed | 300000/24h |

7 | Inspect voltage | 1500—2300V |

8 | Inspect method | Head and body each two times |

9 | Control | PLC |

Color:

-

The JB-DCT Dry Electronic Condom Testing Machine is an advanced, high-precision inspection system designed to ensure the highest quality standards in condom manufacturing. It integrates high-voltage modules, detection control modules, intelligent modeling, and a computer-controlled system, delivering exceptional stability, reliability, and accuracy in defect detection. Utilizing a modern advanced computer programming controller and an imported brake motor, this machine achieves superior performance in detecting pinhole defects, significantly exceeding national standards.

Compared to traditional wet electric detection machines, the JB-DCT offers a lower false detection rate and a higher product pass rate, ensuring optimal efficiency in condom production. This third-generation dry-method electronic inspection machine is fully powered by electricity, eliminating the need for air, water, or steam, while consuming only 6KW of power. It is designed to support energy efficiency, emission reduction, environmental protection, and cost savings for manufacturers. Additionally, its compact structure, lightweight design, easy installation, and simplified maintenance make it an ideal choice for modern production facilities.

Key Features & Advantages1. Efficient & Intelligent Design

- Double chain transmission structure ensures stable and synchronized operation.

- Intelligent mold with memory function for optimized detection efficiency.

- Independent high-voltage detection zones for both head and body, improving defect identification.

- Integrated system design, allowing immediate operation upon power-up.

2. High-Performance Defect Detection

- Uses a brake motor to separate qualified products from defective ones with high precision.

- Computer-controlled display and data storage for real-time monitoring and analysis.

- Maximum detection speed of 270 condoms per minute, ensuring high-volume production efficiency.

- Pinholes detected at an average rate below 0.2 per unit, surpassing the national AQL standard.

- Product pass rate of over 98%, with a false detection rate below 30%, outperforming traditional wet-method machines.

3. Energy-Saving & Cost-Effective

- Operates entirely on electric power, requiring no air, water, or steam, reducing operational costs.

- Low energy consumption of just 6KW, contributing to sustainable manufacturing.

- Compact and lightweight design (3T total weight), allowing easy installation, commissioning, and maintenance.

The JB-DCT Dry Electronic Condom Testing Machine is ideal for condom manufacturing companies looking to:

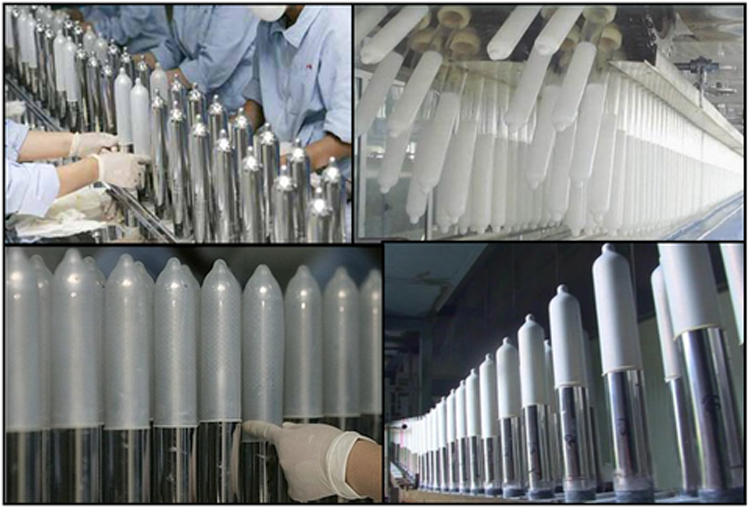

About the Manufacturer

✔ Improve quality assurance through advanced defect detection.

✔ Reduce false detection rates while increasing pass rates.

✔ Lower production costs by eliminating the need for water, air, or steam.

✔ Achieve energy efficiency and environmental compliance.Our company specializes in high-precision quality control solutions for the medical and latex industries. We are dedicated to developing innovative and reliable testing equipment that enhances product safety, production efficiency, and cost-effectiveness for manufacturers worldwide.

-

1

Machine size

7.3m×1.7m×2.3m

2

Powder

6KW

3

Mold pitch

152.4mm

4

Max chain speed

18m/min

5

Mold quantity

208只

6

Speed

300000/24h

7

Inspect voltage

1500—2300V

8

Inspect method

Head and body each two times

9

Control

PLC