<

>

>

-

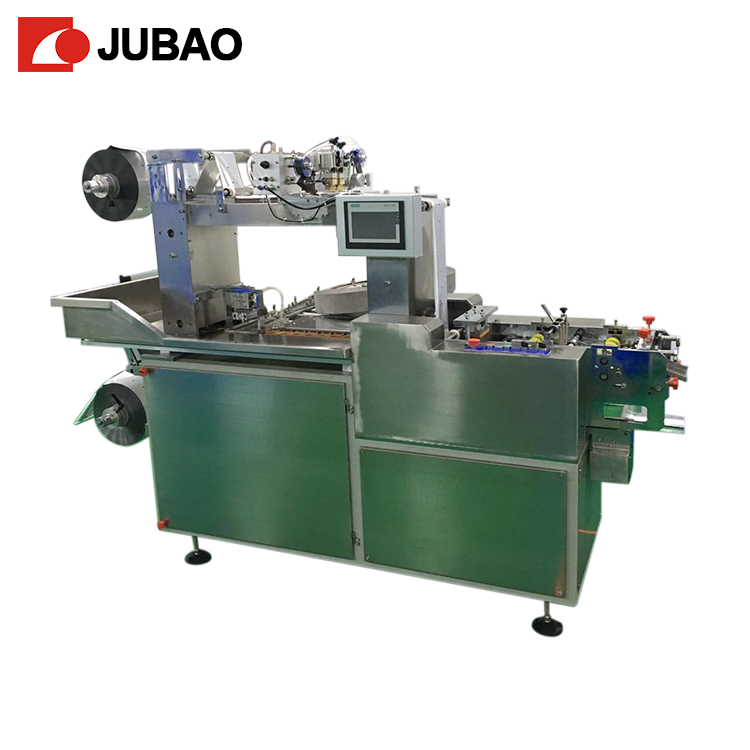

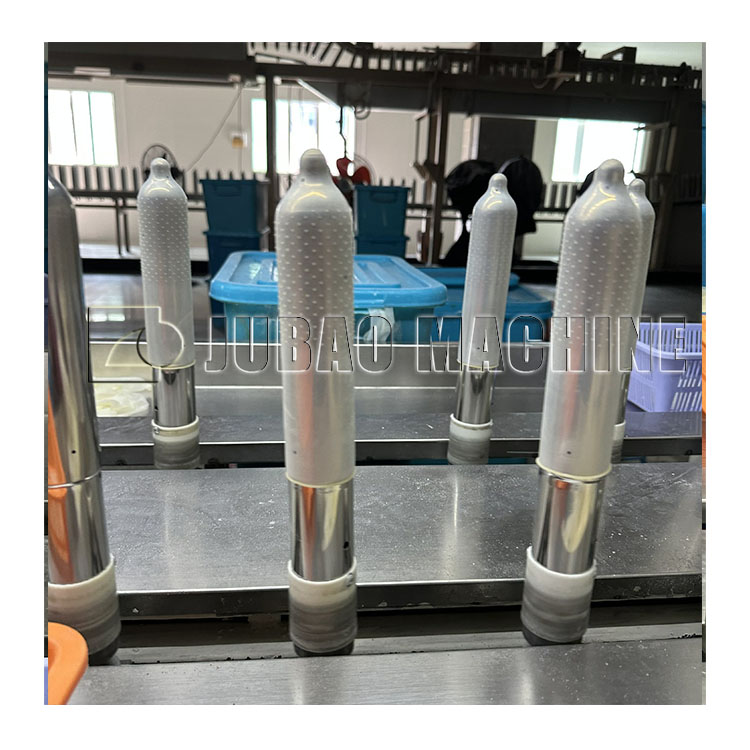

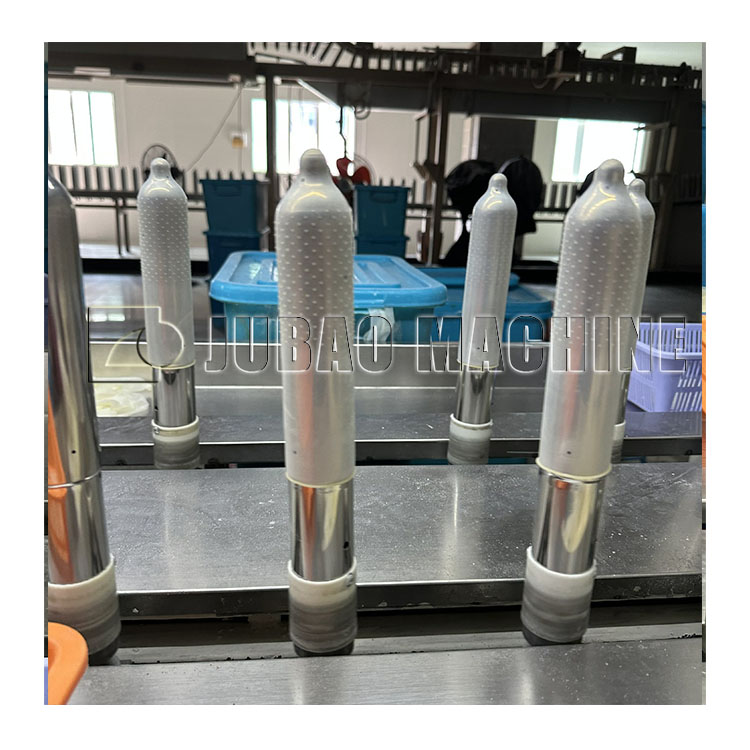

It is composed of high voltage module, detection control module, intelligent model, computer control and so on. The modern advanced computer programming controller is adopted, and the imported brake motor is used to separate, which ensures the stable, reliable and accurate detection of the machine. Improve the quality assurance of testing products to a new height.It is much lower than the AQL value of pinhole water leakage required by the national standard, and the false detection rate of the product is also better than that of the current wet electric detection machine. The third-generation new type condom dry-method electric inspection machine is powered by electric energy throughout the inspection process, and does not require air, water and steam, and the motor power is only 6KW.It creates favorable conditions for enterprises to save energy, reduce emissions, protect the environment, and reduce production costs. At the same time, it also has the advantages of light weight, small footprint, easy installation, convenient commissioning and maintenance.

Technical characteristics of condom dry electric inspection machine1. Double chain transmission structure;2. Intelligent mold with memory function;3. High-voltage detection in the independent super-long area of the head and body;4. Use brake motors to separate genuine products and waste products;5. Computer display and storage of testing parameters;6. The integrated design of the whole machine, it can be produced when the power is turned on;7. The installed capacity of the whole machine is 6KW, and the weight of the whole machine is 3T;8. The maximum detection capacity is 270 condoms per minute;9. The average value of the pinhole process of the product after the electric inspection is below 0.2, the pass rate of the product after the electric inspection is above 98%, and the false detection rate is below 30%;

Technical characteristics of condom dry electric inspection machine1. Double chain transmission structure;2. Intelligent mold with memory function;3. High-voltage detection in the independent super-long area of the head and body;4. Use brake motors to separate genuine products and waste products;5. Computer display and storage of testing parameters;6. The integrated design of the whole machine, it can be produced when the power is turned on;7. The installed capacity of the whole machine is 6KW, and the weight of the whole machine is 3T;8. The maximum detection capacity is 270 condoms per minute;9. The average value of the pinhole process of the product after the electric inspection is below 0.2, the pass rate of the product after the electric inspection is above 98%, and the false detection rate is below 30%;

-

Technica information

1

Machine size

7.3m×1.7m×2.3m

2

Powder

6KW

3

Mold pitch

152.4mm

4

Max chain speed

18m/min

5

Mold quantity

208只

6

Speed

300000/24h

7

Inspect voltage

1500—2300V

8

Inspect method

Head and body each two times

9

Control

PLC