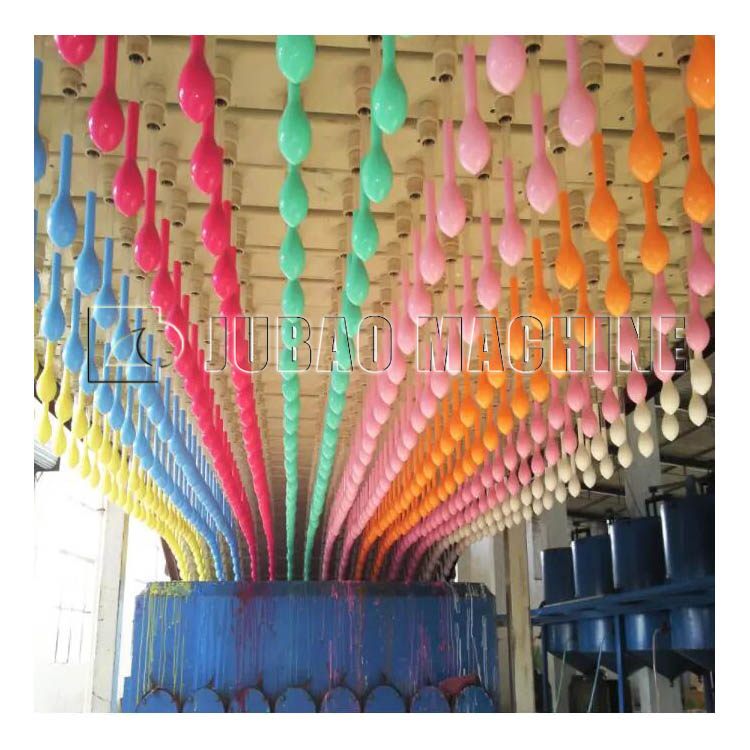

Advanced Latex Balloon Dipping Machine for Efficient Production JB-QQ60

PRODUCT SERIES: Balloon Machine Series

- Material Compatibility: Latex

- Process Automation: Fully automated with multiple quality control checkpoints

- Machine Durability: Rust-resistant and designed for high-volume usage

Color:

-

Product Description

The latex balloon dipping machine is designed to streamline the manufacturing process of high-quality latex balloons, ensuring precision and efficiency at every step. This advanced equipment incorporates an automated system that delivers consistent results while reducing labor and material wastage. The machine is ideal for large-scale production, offering flexibility and reliability to meet various production demands.Key Features

- Efficient Process Flow: The machine automates critical steps including milling, vulcanization, stripping off, and dipping, ensuring smooth and continuous operations.

- Superior Cleaning Mechanism: Equipped with acid wash, brush wash, and hot water wash stages to maintain cleanliness and product quality.

- Customizable Outputs: Designed for various balloon specifications, accommodating diverse production requirements.

- Durable Construction: Built with high-quality materials for long-lasting performance and minimal maintenance.

Craftwork Flow

- Milling

- Vulcanization

- Stripping Off

- Acid Wash

- Brush Wash

- Hot Water Wash

- Dipping Coagulant

- Dipping Latex

- Drying

- Beading

- Drying

- Add Slurry

Applications

The latex balloon dipping machine is suitable for factories producing decorative, party, and industrial balloons. It ensures consistent product quality, making it an essential tool for large-scale production lines. -

Technical parameters:

Model

JB-QQ45

JB-QQ60

JB-QQ80

JB-QQ100

Dimension(L*W*H*)

45*2.23*3.15m

60*2.23*3.15 m

80*2.23*3.15m

100*2.23*3.15m

Layer

2

2

2

2

Color/time

6

6

8

8

Mold/row

12

12

16

18

12"/9" /7"

Capacity(pcs/hr)

16000-24000

21000-32000

39000-58000

48000-73000

Heat(Kcal/hr)

250000

400000

500000

625000

Power(kw/hr)

23

29

32

40

Weight(ton)

35

42

45

56

Heating Source

Steam、Thermos oil、Natural Gas、Electricity Etc.

Voltage(V)

380/220V 50-60HZ