Which Foods Cannot Be Vacuum Sealed?

Table of Contents

- Introduction

- Understanding the Risks of Improper Vacuum Sealing

- Foods That Should Not Be Vacuum Sealed

- Soft Cheeses and Dairy Products

- Raw Fresh Vegetables and Mushrooms

- Fresh Garlic and Onions

- Safe Alternatives and Workarounds

- Proper Vacuum Sealing Techniques

- What Vacuum Packing Machine Manufacturers Recommend

- Conclusion

Introduction

While vacuum sealing is an excellent method for preserving many types of food, not all foods are suitable for this preservation technique. Understanding which foods cannot be vacuum sealed is crucial for food safety, preventing spoilage, and avoiding potential health risks. Improper vacuum sealing can create dangerous conditions that promote bacterial growth, particularly botulism, which thrives in oxygen-free environments.

Any reputable vacuum packing machine manufacturer will emphasize the importance of knowing which foods require special handling or should be avoided altogether when vacuum sealing. This guide will help you identify risky foods and provide safe alternatives for proper food preservation.

Understanding the Risks of Improper Vacuum Sealing

The primary concern with vacuum sealing certain foods is the creation of an anaerobic (oxygen-free) environment that can promote the growth of Clostridium botulinum bacteria. This pathogen produces botulinum toxin, one of the most deadly substances known, which can cause severe illness or death.

Botulism bacteria are naturally present in soil and can contaminate various foods, particularly those with low acidity. When oxygen is removed through vacuum sealing and the food is stored at room temperature or improper refrigeration temperatures, these bacteria can multiply rapidly and produce toxins without any visible signs of spoilage.

Additionally, some foods contain enzymes that continue to break down cellular structures even when vacuum sealed, leading to undesirable texture changes, off-flavors, or excessive gas production that can compromise the seal. Understanding these risks helps explain why certain foods require special treatment or should be avoided entirely.

Foods That Should Not Be Vacuum Sealed

Fresh Soft Cheeses

Soft, fresh cheeses like ricotta, fresh mozzarella, cream cheese, and goat cheese contain high moisture content and active cultures that continue to produce gases after packaging. Vacuum sealing these cheeses can accelerate spoilage, create unpleasant odors, and cause the packaging to balloon or burst.

Raw Mushrooms

Fresh mushrooms are among the most problematic foods for vacuum sealing. They naturally release moisture and gases as they age, and their porous structure continues biological processes even when refrigerated. Vacuum sealing raw mushrooms creates a slimy texture, accelerates decomposition, and can produce dangerous bacterial growth.

Fresh Bananas

Bananas continue to ripen and release ethylene gas after harvesting. Vacuum sealing fresh bananas accelerates the ripening process, turns them black quickly, and creates mushy, unappetizing results. The removed oxygen actually speeds up enzymatic browning rather than preventing it.

Cruciferous Vegetables

Raw broccoli, cauliflower, Brussels sprouts, and cabbage emit gases naturally and contain enzymes that remain active even when refrigerated. Vacuum sealing these vegetables raw leads to unpleasant odors, off-flavors, and potential seal failure due to gas buildup.

Soft Cheeses and Dairy Products

Beyond fresh soft cheeses, other dairy products require caution when vacuum sealing. Active cultures in yogurt, kefir, and cultured buttermilk continue producing gases that can compromise vacuum seals. These products are best stored in their original containers or transferred to airtight containers without vacuum sealing.

However, aged hard cheeses like cheddar, parmesan, and gouda can be successfully vacuum sealed after proper preparation. Most vacuum packing machine manufacturer guidelines recommend cutting hard cheeses into smaller portions, ensuring they’re completely dry, and using commercial-grade bags to prevent moisture buildup.

For semi-soft cheeses like mozzarella or provolone, freezing before vacuum sealing provides better results. The freezing process halts enzymatic activity and bacterial growth temporarily, making vacuum sealing safer and more effective for long-term storage.

Raw Fresh Vegetables and Mushrooms

Most raw fresh vegetables should not be vacuum sealed without blanching first. Vegetables like green beans, asparagus, corn, peas, and leafy greens contain enzymes that cause deterioration even in oxygen-free environments. These enzymes break down cell walls, creating mushy textures and off-flavors.

Raw garlic presents particular concerns due to its low acidity and potential for botulism growth when stored in oxygen-free environments at room temperature. Fresh garlic cloves contain moisture and natural compounds that, when vacuum sealed, create ideal conditions for dangerous bacterial growth.

Mushrooms deserve special mention as they’re particularly unsuitable for raw vacuum sealing. Their high water content, porous structure, and active enzymes make them prone to rapid deterioration. Experienced vacuum packing machine manufacturer technicians consistently advise cooking mushrooms thoroughly before vacuum sealing or using alternative storage methods.

Fresh Garlic and Onions

Fresh garlic and onions in their raw state pose significant botulism risks when vacuum sealed. These allium vegetables have low acidity levels (pH above 4.6) that don’t inhibit botulism bacteria growth. When stored vacuum-sealed at room temperature or even in marginal refrigeration conditions, they can become dangerous.

Whole raw onions also release moisture and gases during storage, which can compromise vacuum seals and create spoilage conditions. The sulfur compounds in onions continue to break down cellular structures, leading to unpleasant odors and textures when vacuum sealed raw.

Professional food safety experts and every responsible vacuum packing machine manufacturer recommend either cooking these vegetables thoroughly before vacuum sealing or storing them using traditional methods. Roasted garlic or caramelized onions, when properly cooled and refrigerated, can be safely vacuum sealed for extended storage.

Safe Alternatives and Workarounds

Blanching Vegetables

For vegetables that cannot be vacuum sealed raw, blanching provides an effective solution. This process involves briefly boiling vegetables (typically 2-5 minutes depending on the vegetable), then immediately plunging them into ice water to stop the cooking process. Blanching deactivates enzymes that cause deterioration and makes vegetables safe for vacuum sealing.

Flash Freezing

Flash freezing items before vacuum sealing works well for delicate foods that might be crushed by the vacuum process or that release excessive moisture. Freeze items on a tray until solid, then vacuum seal while still frozen. This technique works particularly well for berries, mushrooms (after cooking), and soft fruits.

Modified Atmosphere Packaging

Some foods benefit from modified atmosphere packaging rather than complete vacuum sealing. This technique removes most air but leaves a small amount of gas (often nitrogen or carbon dioxide) to prevent crushing delicate items. Many advanced vacuum packing machine manufacturer models offer this option.

Traditional Storage Methods

For foods that simply don’t work well with vacuum sealing, traditional storage remains the best option. Store soft cheeses in their original packaging, keep mushrooms in paper bags in the refrigerator, maintain garlic and onions in cool, dry, well-ventilated areas, and use airtight containers rather than vacuum bags for items that produce gases.

Proper Vacuum Sealing Techniques

When vacuum sealing approved foods, following proper techniques ensures safety and quality. Always start with clean, dry food surfaces, as excess moisture can compromise seals and promote bacterial growth. Pat proteins dry with paper towels and ensure vegetables are thoroughly drained after blanching.

Temperature control is critical for food safety. Refrigerate or freeze vacuum-sealed foods promptly, maintaining temperatures below 40°F (4°C) for refrigeration or below 0°F (-18°C) for freezing. Never vacuum seal foods and leave them at room temperature for extended periods, as this creates dangerous conditions for bacterial growth.

Label all vacuum-sealed packages with contents and dates to maintain proper rotation. Even vacuum-sealed foods have limited storage lives—typically 1-2 weeks for refrigerated items and 2-3 years for frozen items, depending on the food type.

Use appropriate bag thickness for your application. Heavier, puncture-resistant bags work better for items with sharp edges or bones. Any quality vacuum packing machine manufacturer provides detailed specifications about compatible bag types and recommended applications.

What Vacuum Packing Machine Manufacturers Recommend

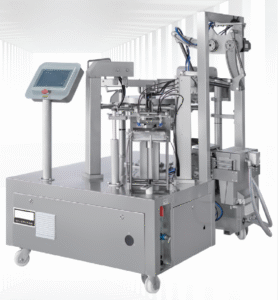

Responsible vacuum packing machine manufacturer companies provide comprehensive food safety guidelines with their equipment. These guidelines typically emphasize the importance of understanding food characteristics, pH levels, and storage requirements before vacuum sealing.

Leading manufacturers include safety information about botulism risks, proper refrigeration temperatures, and foods that require special handling. They often provide detailed charts showing recommended vacuum levels for different food types, appropriate sealing times, and storage duration guidelines.

Professional-grade equipment from reputable vacuum packing machine manufacturer sources often includes adjustable vacuum settings that allow gentler processing for delicate items. These machines may feature pulse modes, adjustable sealing temperatures, and programmable cycles designed for specific food categories.

Manufacturers also stress the importance of regular equipment maintenance for food safety. Clean sealing bars, replace worn gaskets, and maintain vacuum pumps according to manufacturer schedules to ensure consistent, reliable sealing that prevents contamination and spoilage.

Many vacuum packing machine manufacturer companies now offer educational resources, including videos, detailed manuals, and customer support lines to help users understand proper food handling and vacuum sealing techniques. Taking advantage of these resources significantly improves food safety outcomes.

Conclusion

Understanding which foods cannot be vacuum sealed is essential for food safety and quality preservation. Raw soft cheeses, fresh mushrooms, cruciferous vegetables, fresh garlic and onions, and certain other high-moisture or gas-producing foods should be avoided or require special preparation before vacuum sealing.

The primary concern with improper vacuum sealing is creating conditions favorable for botulism bacteria growth. By following guidelines from food safety experts and reputable vacuum packing machine manufacturer sources, you can safely use vacuum sealing for appropriate foods while avoiding dangerous practices.

When in doubt about whether a food is suitable for vacuum sealing, err on the side of caution. Use alternative storage methods, consult manufacturer guidelines, or properly prepare foods through blanching, cooking, or freezing before vacuum sealing. These precautions ensure that vacuum sealing remains a safe, effective preservation method.

With proper knowledge and technique, vacuum sealing provides excellent food preservation for countless items. Focus on foods that work well with the process, follow recommended procedures, and maintain appropriate storage temperatures to maximize both safety and quality in your food preservation efforts.

Need Reliable Vacuum Packing Equipment with Safety Features?

We are a professional vacuum packing machine manufacturer, dedicated to providing high-quality equipment with comprehensive safety guidelines and support. Our machines feature adjustable settings, reliable sealing technology, and come with detailed food safety documentation to help you vacuum seal foods properly and safely.

Contact us today to learn more about our vacuum packing solutions and how we can support your food preservation needs with expert guidance and top-tier equipment.