What are the Machines Used for Food Packaging?

Table of Contents

- 1. Introduction

- 2. Primary Packaging Machines

- 3. Specialized Packaging Machines

- 4. Secondary Packaging Machines

- 5. Labeling and Coding Machines

- 6. Quality Control and Inspection Machines

- 7. Conveyor and Material Handling Systems

- 8. Industry-Specific Packaging Machines

- 9. Automation and Integration Technologies

- 10. Choosing the Right Food Packaging Machine

- 11. Conclusion

Introduction

Food packaging plays a critical role in preserving freshness, ensuring safety, extending shelf life, and maintaining product quality from manufacturer to consumer. The modern food packaging industry relies on sophisticated machinery designed to handle diverse products ranging from liquids and powders to solid foods and delicate items.

Understanding the various machines used for food packaging is essential for food manufacturers, packaging engineers, and business owners looking to optimize their production lines. This comprehensive guide explores the different types of packaging equipment, their functions, and applications across the food industry.

Primary Packaging Machines

Primary packaging machines directly contact the food product and form the first layer of protection. These are among the most critical machines used for food packaging operations.

Filling Machines

Filling machines are essential equipment that accurately dispense predetermined quantities of food products into containers. The type of filling machine depends on the product’s physical properties and consistency.

Liquid filling machines are designed for beverages, oils, sauces, and other liquid products. They include gravity fillers for thin liquids, piston fillers for thicker products like ketchup and mayonnaise, and pump fillers for various viscosities. These machines offer precision filling with minimal product waste and can handle production speeds ranging from 20 to 1,200 bottles per minute depending on automation level.

Powder filling machines handle dry products such as flour, spices, coffee, and protein powders. They utilize auger fillers for consistent volumetric filling, vacuum fillers for fine powders, and gravimetric fillers for weight-based accuracy. Modern powder fillers incorporate dust extraction systems to maintain clean working environments.

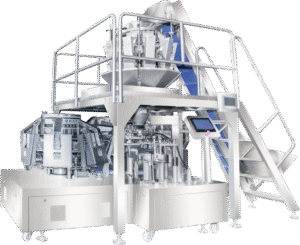

Solid and piece filling machines are used for discrete items like candies, nuts, frozen foods, and snacks. These include counting machines for individual pieces, multi-head weighers for accurate weight-based filling, and cup fillers for consistent volumetric dispensing.

Sealing Machines

Sealing machines create airtight closures to protect food products from contamination and preserve freshness. These versatile machines used for food packaging employ various sealing technologies.

Heat sealing machines use controlled heat to bond thermoplastic materials together. Band sealers provide continuous sealing for bags and pouches, impulse sealers offer precise control for thin films, and induction sealers create tamper-evident seals on bottle caps without contact.

Form-Fill-Seal (FFS) machines represent integrated systems that form packages from roll stock film, fill them with product, and seal them in a continuous operation. Vertical FFS machines handle free-flowing products like chips and grains, while horizontal FFS machines are ideal for solid products and bars.

Wrapping Machines

Wrapping machines enclose products in protective film or paper materials. Flow wrapping machines, also known as horizontal form-fill-seal machines, create sealed packages with crimped ends, perfect for baked goods, candy bars, and fresh produce. Overwrapping machines apply decorative or protective film around boxes or trays, commonly seen in tea boxes and gift sets.

Vacuum Packaging Machines

Vacuum packaging machines remove air from packages before sealing, significantly extending shelf life by reducing oxidation and microbial growth. Chamber vacuum machines place the entire package inside a chamber for evacuation, ideal for liquids and marinades. External vacuum machines seal the bag outside the chamber, suitable for solid products. Skin packaging machines conform the film tightly to the product surface, creating an attractive presentation for fresh meats and seafood.

Specialized Packaging Machines

Certain food products require specialized machines used for food packaging tailored to their unique characteristics and packaging requirements.

Blister Packaging Machines

Blister packaging machines create formed plastic cavities sealed to backing material, commonly used for portion-controlled items like butter pats, cheese cubes, and individual candy servings. These machines thermoform plastic sheets, fill the cavities with product, and seal them with lidding material in a continuous process.

Canning Machines

Canning operations require comprehensive systems including can filling machines that dispense products into metal cans with precision, seaming machines that attach lids using double-seam technology, and retort systems for sterilization to ensure long-term shelf stability. Modern canning lines can process hundreds of cans per minute with automated quality checks.

Bottling Machines

Bottling machines represent complete systems for liquid food products including rinsing machines that clean bottles before filling, filling and capping machines for beverages, juices, and oils, and pressure-sensitive labeling systems. Rotary bottling machines can achieve speeds exceeding 1,000 bottles per minute for high-volume production.

Pouch Packaging Machines

Pouch packaging has gained popularity due to its convenience and material efficiency. Stand-up pouch machines create self-supporting packages with zip closures, spout pouch machines install fitments for easy dispensing of liquids, and retort pouch machines produce shelf-stable packages for ready-to-eat meals.

Secondary Packaging Machines

Secondary packaging machines group primary packages together for distribution and retail display.

Cartoning Machines

Cartoning machines erect, fill, and close cartons automatically. Horizontal cartoners load products horizontally and are ideal for trays, bottles, and pouches. Vertical cartoners drop products from above, perfect for bags and flexible packages. End-load cartoners insert products from the end, commonly used for pharmaceutical and food applications.

Case Packing Machines

Case packing machines organize products into shipping cases efficiently. Robotic case packers use articulated arms for flexible handling of various package sizes and patterns. Drop packers place products directly into cases from above at high speeds. Wrap-around case packers fold corrugated material around product groups, eliminating the need for pre-formed cases.

Shrink Wrapping Machines

Shrink wrapping machines bundle multiple products together using heat-shrinkable film. These systems include film wrappers that envelope products in film, heat tunnels that shrink the film to conform tightly, and cooling sections for package stabilization. Shrink wrapping provides tamper evidence and dust protection while allowing product visibility.

Labeling and Coding Machines

Labeling and coding equipment apply essential information to packages and are indispensable machines used for food packaging operations.

Labeling machines include pressure-sensitive label applicators for front and back labels, sleeve labeling machines that apply shrink sleeves for 360-degree graphics, and hot melt glue labelers for paper labels on bottles and jars.

Coding and marking machines print batch numbers, expiration dates, and barcodes directly on packages. Inkjet printers offer high-speed printing on various surfaces, laser coders provide permanent marks without consumables, and thermal transfer printers produce high-resolution codes on labels and films.

Quality Control and Inspection Machines

Quality control machines ensure that only properly packaged products reach consumers. These critical machines used for food packaging lines include:

- Metal detectors: Identify metallic contamination in packaged foods to prevent consumer harm and brand damage

- X-ray inspection systems: Detect foreign objects including glass, stone, bone, and dense plastics while verifying fill levels and seal integrity

- Vision inspection systems: Use cameras and image processing to check label placement, print quality, seal integrity, and package orientation

- Checkweighers: Verify package weights to ensure compliance with fill weight regulations and detect missing products or components

- Leak detection systems: Test package integrity using vacuum decay, pressure decay, or ultrasonic methods

Conveyor and Material Handling Systems

Conveyor systems connect different packaging machines and facilitate smooth product flow throughout the production line. Belt conveyors transport packages on flat belts with adjustable speeds, roller conveyors use rotating rollers for heavier products, and chain conveyors handle high-temperature applications.

Accumulation conveyors create buffer zones to balance line speeds, while incline and decline conveyors change elevation between processing areas. Spiral conveyors save floor space when vertical movement is needed in compact facilities.

Industry-Specific Packaging Machines

Different food sectors require specialized equipment tailored to their products.

Bakery packaging machines include bread slicing and bagging systems, tray forming and sealing machines for cakes and pastries, and flow wrappers for individual baked items. These machines handle delicate products gently while maintaining hygiene standards.

Meat and poultry packaging equipment features thermoforming machines for modified atmosphere packaging, tray sealers for fresh cuts, and vacuum skin packaging for extended shelf life. These machines operate in refrigerated environments and meet strict sanitation requirements.

Dairy packaging machines process milk, yogurt, cheese, and butter with aseptic filling systems for ultra-high temperature treated products, cup filling and sealing machines for yogurt and desserts, and block forming and wrapping machines for butter and cheese.

Snack food packaging machinery includes vertical form-fill-seal machines for chips and crackers, multi-lane stick pack machines for single servings, and combination weighing systems for mixed snack packs.

Automation and Integration Technologies

Modern machines used for food packaging increasingly incorporate advanced automation and connectivity features.

Programmable Logic Controllers (PLCs) manage machine operations with precise timing and coordination, allowing operators to store multiple recipes and switch between products quickly. Human-Machine Interfaces (HMIs) provide touchscreen controls for intuitive operation and real-time monitoring of production metrics.

Robotics handle pick-and-place operations, product orientation, and case packing with flexibility to accommodate product changes. Collaborative robots work alongside human operators for tasks requiring dexterity and judgment.

Internet of Things (IoT) connectivity enables remote monitoring and predictive maintenance by collecting machine performance data, analyzing trends to predict component failures, and scheduling maintenance before breakdowns occur. This technology reduces unplanned downtime and optimizes overall equipment effectiveness.

Artificial Intelligence and machine learning applications optimize packaging parameters in real-time, improve quality inspection accuracy, and adapt to product variations automatically.

Choosing the Right Food Packaging Machine

Selecting appropriate machines used for food packaging requires careful consideration of multiple factors.

Product characteristics including physical state, viscosity, temperature sensitivity, and fragility determine compatible machine types. Liquid products require different handling than powders or solid pieces.

Production volume requirements influence whether manual, semi-automatic, or fully automatic machines are most cost-effective. Small-batch production may not justify high-speed automated equipment, while large volumes require maximum efficiency.

Package format preferences including material type, size range, and closure method must match machine capabilities. Some machines offer quick changeover between formats, while others are dedicated to specific package types.

Space constraints and facility layout affect machine footprint and configuration. Compact facilities may require vertical machines or multi-function equipment to maximize available space.

Budget considerations encompass initial investment, operating costs, maintenance expenses, and expected return on investment. Higher-priced automated equipment may offer lower per-unit costs over time.

Regulatory compliance requirements vary by region and product category. Machines must meet food safety standards, facilitate proper cleaning and sanitation, and support traceability requirements.

Future scalability needs should influence equipment selection. Modular systems allow capacity expansion, while flexible machines accommodate product line extensions without complete replacement.

Conclusion

The variety of machines used for food packaging reflects the diverse needs of the modern food industry. From filling and sealing machines that provide primary product protection to sophisticated inspection systems ensuring quality and safety, each piece of equipment plays a vital role in delivering products to consumers.

Understanding the capabilities and applications of different packaging machines enables food manufacturers to make informed decisions about equipment investments. Whether you’re establishing a new production line, upgrading existing equipment, or expanding into new product categories, selecting the right combination of packaging machinery is crucial for operational efficiency, product quality, and business success.

As technology continues to advance, packaging machinery evolves with increased automation, better integration, and enhanced intelligence. Staying informed about emerging technologies and industry trends helps manufacturers maintain competitive advantages and meet changing consumer demands.

When evaluating machines used for food packaging, consider not only immediate needs but also long-term goals, regulatory landscapes, and market trends. Consulting with equipment suppliers, attending industry trade shows, and visiting demonstration facilities provide valuable insights for making optimal packaging machinery investments.