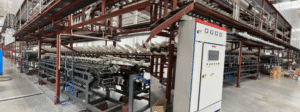

Product Details:

- Versatile Material Handling: Expertly processes PVC emulsion, latex, vinyl, and nitrile, enabling the production of a diverse range of glove types.

- Enhanced Double Mode Functionality: The innovative double mode design increases chaining speed by 10%, outperforming industry standards. This feature ensures high-temperature resistance and quick conversion rates, maximizing productivity.

- High-Efficiency Fixtures: Incorporates lightweight, high-temperature resistant fixtures that are 50% lighter than traditional iron fixtures, reducing energy consumption by up to 30% and accelerating operational speed.

- Rapid Heating System: The advanced combustion chamber, equipped with a high-performance burner, swiftly adjusts oven temperatures. This system is more energy-efficient and faster than traditional boilers requiring 25 hours to reach the desired temperature.

- Comprehensive Tank Heating: Maintains consistent processing conditions with tank heating, ensuring top-quality glove production.

Product Attributes:

- Main Products: Manufactures PVC, latex, vinyl, nitrile, and neoprene gloves for examination, surgical, and industrial use.

- Key Advantages:

- Double mode for enhanced speed and efficiency.

- Lightweight, high-temperature resistant fixtures for continuous 24-hour operation.

- Rapid measurement and energy-saving design.

- Advanced heating system for efficient temperature control.

- Additional Features: Includes tank heating for consistent processing and superior product quality.

Transform your glove manufacturing capabilities with the JB-SBA Multi-Material Glove Dipping Machine, designed for superior efficiency, reliability, and production quality.

Glove Production Line Detail:

Finished products:

Tip: There is a need for more detailed information, please call customer service!