How Does a Condom Machine Work? A Comprehensive Guide to Vending and Manufacturing

Table of Contents

- Introduction

- Understanding Condom Vending Machines

- The Complete Condom Making Machine Process

- Advanced Condom Machine Technology

- Installation and Maintenance

- Benefits and Applications

- Future of Condom Machines

- Conclusion

Introduction

Condom machines play a crucial role in public health and accessibility, providing convenient access to protection while maintaining privacy. From vending machines in public restrooms to sophisticated manufacturing equipment, these devices have evolved significantly over the decades. This comprehensive guide explores how both condom vending machines and condom making machines operate, their technology, and their impact on society.

Understanding Condom Vending Machines

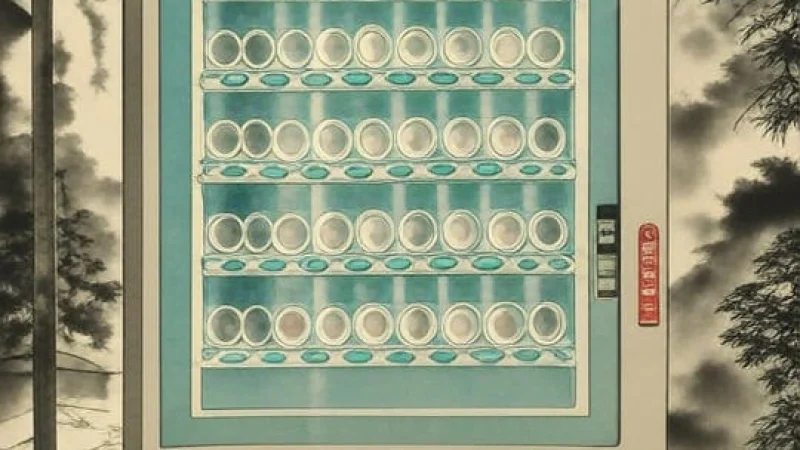

How Condom Vending Machines Function

A condom machine operates through a relatively straightforward mechanical or electronic system designed for reliability and ease of use. The basic functionality involves several key components working in harmony.

The coin mechanism forms the heart of most traditional condom machines. When a user inserts the correct coins, the mechanism validates the currency and triggers the dispensing process. Modern machines often include bill validators and even contactless payment options like credit cards or mobile payment systems.

Internal Mechanism and Components

The product storage system typically consists of multiple slots or compartments, each designed to hold different brands or types of condoms. Spring-loaded mechanisms ensure products are properly positioned for dispensing. When activated, a motor-driven system pushes the selected product through a delivery chute.

Security and Anti-Vandalism Features

Most condom machines incorporate robust security measures to prevent theft and vandalism. Heavy-duty steel construction, tamper-resistant locks, and reinforced coin boxes are standard features. Some advanced models include alarm systems and surveillance camera integration.

The Complete Condom Making Machine Process

Manufacturing Overview

A condom making machine represents sophisticated industrial equipment designed to produce latex condoms through an automated process. The manufacturing begins with latex preparation, where natural rubber latex is mixed with various chemicals including sulfur for vulcanization, accelerators, and stabilizers.

Dipping Process Technology

The core of condom manufacturing involves aluminum formers shaped like male anatomy. These formers are first heated, then dipped into coagulant solution before being immersed in the latex compound. The dipping process typically occurs multiple times to achieve the desired thickness and strength.

Quality Control and Testing

Modern condom making machines incorporate extensive quality control systems. Each condom undergoes electronic testing for holes, strength testing through inflation, and visual inspection. Automated rejection systems remove defective products from the production line.

Packaging and Finishing

After production and testing, condoms move through automated packaging systems that apply lubricants, fold the products, and seal them in individual packages. High-speed packaging machines can process thousands of units per hour while maintaining sterile conditions.

Advanced Condom Machine Technology

Smart Vending Solutions

Contemporary condom machine technology increasingly features smart integration. These systems can track inventory levels, process various payment methods, and even connect to mobile apps for enhanced user experience. Some machines offer product customization options and educational materials.

IoT Connectivity and Monitoring

Internet of Things (IoT) technology enables remote monitoring of condom machines. Operators can track sales data, inventory levels, and maintenance requirements in real-time. This connectivity reduces operational costs and ensures machines remain stocked and functional.

Sustainable Manufacturing Practices

Modern condom making machines increasingly incorporate environmentally friendly features. Energy-efficient heating systems, waste reduction mechanisms, and recyclable packaging integration reflect growing environmental consciousness in the industry.

Installation and Maintenance

Strategic Placement Considerations

Successful condom machine deployment requires careful location analysis. High-traffic areas like universities, nightlife districts, and healthcare facilities typically generate optimal usage. Accessibility, privacy, and local regulations all influence placement decisions.

Regular Maintenance Requirements

Both vending and manufacturing machines require systematic maintenance schedules. For vending machines, this includes coin mechanism cleaning, product rotation, and security system checks. Manufacturing equipment demands more complex maintenance including calibration, component replacement, and safety system verification.

Troubleshooting Common Issues

Common problems include coin jams, product delivery failures, and electronic malfunctions. Proper maintenance protocols and operator training significantly reduce downtime and ensure reliable operation.

Benefits and Applications

Public Health Impact

Condom machines contribute significantly to public health initiatives by increasing access to protection. Studies demonstrate that convenient access correlates with increased usage rates, particularly among younger demographics who may feel uncomfortable purchasing condoms in traditional retail settings.

Privacy and Accessibility

The anonymous nature of machine purchases eliminates embarrassment factors that might otherwise prevent condom acquisition. 24/7 availability ensures access regardless of store hours or location constraints.

Economic Considerations

For operators, condom machines offer attractive profit margins and relatively low maintenance requirements. The recurring revenue model provides stable income streams while serving important community health needs.

Future of Condom Machines

Technological Innovations

Emerging technologies promise to further enhance condom machine functionality. Artificial intelligence integration could enable personalized recommendations, while advanced materials science may revolutionize manufacturing processes.

Market Expansion

Growing awareness of sexual health and changing social attitudes continue expanding the condom machine market. International deployment in developing regions represents significant growth opportunities.

Integration with Health Services

Future condom machines may integrate with broader health service networks, offering STI testing capabilities, educational resources, and connections to healthcare providers.

Conclusion

Condom machines, whether for vending or manufacturing, represent essential components of modern public health infrastructure. Vending machines provide crucial accessibility and privacy, while manufacturing equipment ensures quality and availability of protection products. As technology continues advancing, these machines will likely become even more sophisticated, efficient, and integral to global health initiatives.

Understanding how these systems work helps stakeholders make informed decisions about deployment, maintenance, and innovation. Whether you’re considering installing vending machines in your facility or exploring manufacturing opportunities, the technology behind condom machines continues evolving to better serve public health needs.

Ready to learn more about condom machine solutions? Contact industry experts today to explore vending machine opportunities for your location or discover the latest in manufacturing technology. Your investment in accessible protection contributes to healthier communities worldwide. Don’t wait – take action now to make a positive impact on public health in your area.