In the realm of personal protective equipment (PPE), few products have garnered as much attention and demand as nitrile gloves. Their resilience, puncture resistance, and chemical compatibility make them indispensable in industries ranging from healthcare to automotive, food processing to janitorial services. As the world continues to grapple with pandemic-driven safety concerns and heightened hygiene standards, the question of "How big is the nitrile glove market?" becomes increasingly pertinent.

The Growing Market Landscape

The nitrile glove market is experiencing unprecedented growth, fueled by a multitude of factors. Firstly, the COVID-19 pandemic has underscored the importance of PPE, leading to a surge in demand for gloves across various sectors. Secondly, the superior properties of nitrile over traditional latex gloves have prompted a shift in consumer preference, particularly among those with allergies or sensitivities. Lastly, advancements in manufacturing technologies and increasing awareness about occupational health and safety have further bolstered the market's expansion.

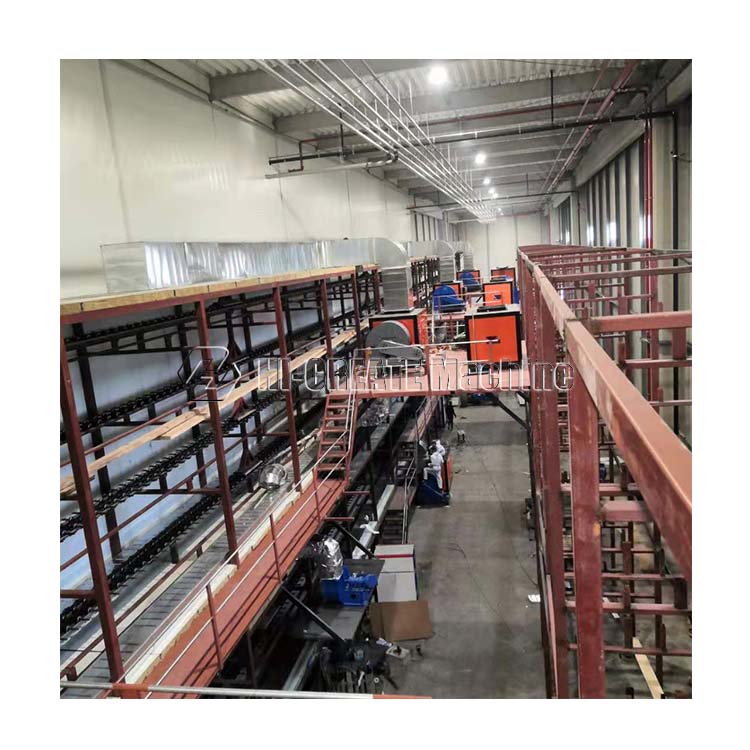

Jubao: Leading the Way in Glove Production

At the forefront of this booming industry stands Jubao, a renowned manufacturer of innovative glove production lines, including the state-of-the-art JB-SBA Nitrile Latex PVC Glove Dipping Machine. Jubao, with its roots firmly planted in China, has established itself as a trusted partner for wholesale manufacturers seeking to capitalize on the growing nitrile glove market.

The Power of the JB-SBA Dipping Machine

The JB-SBA dipping machine represents a game-changer in the glove production process. This advanced machinery streamlines the dipping, curing, and stripping of nitrile, latex, or PVC glove materials, ensuring consistency, precision, and efficiency at every step. By automating critical production stages, Jubao's machines significantly reduce labor costs, minimize waste, and enhance product quality.