What Are the Machines Used for Food Packaging?

Table of Contents

Introduction

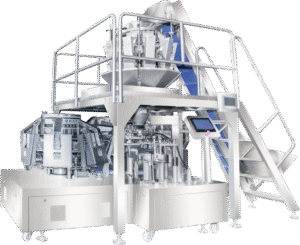

The food packaging industry relies on sophisticated machinery to ensure products are packaged efficiently, safely, and attractively. From small-scale operations to large manufacturing facilities, the right packaging equipment can significantly impact productivity, product quality, and profitability. Understanding the various machines used for food packaging is essential for businesses looking to optimize their production lines and maintain competitive advantages in the market.

Modern food packaging machinery has evolved dramatically over the past decades, incorporating advanced automation, precision controls, and smart technology. Leading food packaging machinery companies continue to innovate, offering solutions that address diverse packaging needs across the food industry. This comprehensive guide explores the essential machines used in food packaging operations.

Filling Machines: Precision and Accuracy

Filling machines are fundamental equipment in food packaging operations, designed to dispense precise quantities of products into containers. These machines handle various food types, from liquids and powders to granules and pastes.

Liquid filling machines are commonly used for beverages, sauces, oils, and dairy products. They employ different filling technologies including gravity filling, piston filling, and volumetric filling, depending on the product’s viscosity and consistency. Modern liquid fillers can achieve high speeds while maintaining accuracy within fractions of a milliliter.

Powder filling machines cater to products like flour, spices, protein powders, and instant beverages. These machines use auger fillers, vacuum fillers, or cup fillers to handle fine to coarse powders without creating excessive dust or waste. Accurate weight control is crucial for regulatory compliance and customer satisfaction.

For semi-solid foods such as peanut butter, jams, and thick sauces, piston fillers and pump fillers provide the necessary force to move viscous products through the filling system. Many food packaging machinery companies offer versatile filling solutions that can be adjusted for different product consistencies.

Sealing Machines: Ensuring Product Freshness

Sealing machines create airtight closures that protect food products from contamination, moisture, and oxygen, thereby extending shelf life and maintaining quality. Various sealing technologies serve different packaging formats and materials.

Heat sealers use controlled heat to bond thermoplastic materials together, creating strong, reliable seals. They are widely used for pouches, bags, and flexible packaging materials. Induction sealers create tamper-evident seals on bottles and jars by heating a foil liner that bonds to the container rim.

Vacuum sealing machines remove air from packages before sealing, which is particularly important for fresh meats, cheese, and other perishable products. This process significantly extends shelf life by reducing oxidation and inhibiting bacterial growth. Many modern vacuum sealers incorporate modified atmosphere packaging (MAP) capabilities, replacing air with protective gas mixtures.

Form-fill-seal machines combine multiple operations by forming packages from roll stock, filling them with product, and sealing them in a continuous process. Vertical form-fill-seal (VFFS) machines are ideal for snacks, frozen foods, and dry products, while horizontal form-fill-seal (HFFS) machines excel with products that need to lay flat during packaging.

Wrapping and Shrink Wrap Machines

Wrapping machines provide protective layers around food products, offering both preservation benefits and attractive presentation. These machines accommodate various wrapping materials and package configurations.

Flow wrap machines, also known as horizontal wrappers, create sealed packages around individual products or product groups. They are commonly used for bakery items, candy bars, fresh produce, and prepared foods. The continuous motion of these machines enables high-speed packaging with minimal film waste.

Shrink wrap machines apply heat-shrinkable film around products, then use heat tunnels to tighten the film, creating a secure, transparent package. This method is popular for multi-pack beverages, bundled products, and retail-ready packaging. Shrink wrapping provides excellent product visibility while protecting against tampering and contamination.

Stretch wrapping equipment is primarily used for palletizing operations, securing multiple cases or packages together for transportation and storage. These machines wrap stretch film around palletized loads, providing stability and protection during handling and shipping.

Labeling and Coding Machines

Labeling and coding equipment apply essential information to packages, including product details, branding, barcodes, and traceability data. Accurate labeling is critical for regulatory compliance and supply chain management.

Pressure-sensitive labelers apply pre-printed labels to various package surfaces, including flat panels, curved surfaces, and irregular shapes. These versatile machines can handle different label sizes and materials, making them suitable for diverse food products from bottles and jars to boxes and bags.

Print-and-apply systems combine printing and labeling in one operation, allowing for variable data printing such as batch numbers, expiration dates, and serialization. This flexibility is valuable for manufacturers who need to change information frequently or implement track-and-trace systems.

Coding machines, including inkjet printers, laser coders, and thermal transfer printers, directly mark packages with production dates, lot codes, and other variable information. Many food packaging machinery companies integrate coding systems into complete packaging lines for seamless operation and quality control.

Cartoning and Case Packing Machines

Cartoning and case packing machines automate the secondary packaging process, grouping primary packages into cartons and cases for retail distribution and shipping.

Horizontal cartoning machines load products horizontally into pre-formed cartons, then close and seal the cartons. These machines are ideal for products like frozen foods, cereals, and bakery items. Vertical cartoning machines load products from above, which works well for bottles, pouches, and tube containers.

Case packers arrange multiple cartons or individual products into shipping cases. Robotic case packers offer maximum flexibility, handling various product configurations and case sizes with quick changeovers. Conventional case packers use mechanical systems to achieve high speeds with specific product formats.

Case erectors automatically form flat cardboard blanks into three-dimensional cases, while case sealers apply tape or glue to secure the filled cases. Integrating these machines creates efficient end-of-line packaging systems that reduce manual labor and improve consistency.

Specialized Packaging Equipment

Beyond standard packaging machinery, specialized equipment addresses unique packaging requirements in the food industry.

Vacuum packaging machines for large-scale operations offer chamber systems that can package multiple products simultaneously. These industrial vacuum packers are essential for meat processing facilities, cheese manufacturers, and prepared meal producers.

Blister packaging machines create formed plastic cavities that hold individual portions or units, then seal them with backing material. This packaging format is common for individual condiment portions, candy, and pharmaceutical-grade food supplements.

Modified atmosphere packaging systems precisely control the gas composition inside packages, replacing oxygen with nitrogen, carbon dioxide, or gas blends. MAP technology is crucial for extending the shelf life of fresh-cut produce, ready-to-eat meals, and other highly perishable foods.

Inspection and quality control equipment, including checkweighers, metal detectors, and X-ray systems, ensure package integrity and product safety. These machines identify underweight packages, detect foreign objects, and verify seal quality before products leave the facility.

Selecting Reliable Food Packaging Machinery Companies

Choosing the right equipment supplier is as important as selecting the appropriate machinery. Reputable food packaging machinery companies offer more than just equipment; they provide expertise, support, and partnership for long-term success.

When evaluating food packaging machinery companies, consider their industry experience and track record with similar products and production scales. Established companies typically offer proven technology, extensive parts availability, and comprehensive service networks. Review their portfolio of successful installations and seek references from current customers.

Technical support and training capabilities distinguish exceptional suppliers from average ones. Look for food packaging machinery companies that provide thorough operator training, detailed documentation, and responsive technical support. Remote diagnostics and preventive maintenance programs can minimize downtime and optimize equipment performance.

Customization capabilities and flexibility are valuable when standard equipment does not perfectly match your needs. The best food packaging machinery companies work collaboratively with customers to adapt machines or develop custom solutions that address specific challenges.

Consider the total cost of ownership, not just the initial purchase price. Evaluate energy efficiency, maintenance requirements, parts costs, and expected equipment lifespan. Reliable food packaging machinery companies provide transparent information about operating costs and help customers make informed investment decisions.

Conclusion

The machines used for food packaging encompass a wide range of specialized equipment, each serving critical functions in the packaging process. From filling and sealing to labeling and case packing, modern packaging machinery enables food manufacturers to achieve high efficiency, consistent quality, and regulatory compliance.

Understanding the capabilities and applications of different packaging machines helps businesses make informed decisions about equipment investments. As technology continues advancing, packaging machinery becomes increasingly sophisticated, incorporating automation, data connectivity, and smart controls that enhance productivity and traceability.

Success in food packaging depends not only on selecting appropriate machinery but also on partnering with reputable suppliers who provide comprehensive support. By working with experienced food packaging machinery companies, manufacturers can optimize their packaging operations and adapt to evolving market demands.

Looking for reliable packaging equipment and expert guidance? We are one of the leading food packaging machinery companies, specializing in comprehensive packaging solutions for the food industry. Our extensive equipment portfolio includes filling machines, sealing systems, wrapping equipment, labeling solutions, and complete packaging lines designed to meet your specific production needs. With decades of industry experience, cutting-edge technology, and dedicated customer support, we help food manufacturers achieve operational excellence and packaging innovation. Contact us today to discuss how our expertise as one of the premier food packaging machinery companies can elevate your packaging operations and drive your business growth.