What is Smart Packaging Technology for Food?

Table of Contents

Smart packaging technology represents a revolutionary advancement in the food industry, transforming traditional packaging from a passive container into an intelligent system that monitors, communicates, and actively preserves food quality. As consumer demands for food safety, transparency, and sustainability continue to grow, smart packaging has emerged as a critical innovation that benefits manufacturers, retailers, and consumers alike.

Understanding Smart Packaging Technology

Smart packaging technology refers to packaging systems that go beyond the basic functions of containment and protection. These advanced solutions incorporate scientific innovations and digital technologies to extend shelf life, monitor product conditions, provide information, and enhance the overall consumer experience. Unlike conventional packaging, smart packaging interacts with the food product or external environment to deliver added value throughout the supply chain.

The concept encompasses two primary categories: active packaging and intelligent packaging. Active packaging systems actively work to improve food preservation by releasing or absorbing substances, while intelligent packaging monitors and communicates information about the product’s condition or the environment inside the package. Many modern solutions combine both approaches to create comprehensive smart packaging systems.

The technology has gained momentum due to increasing food waste concerns, rising consumer awareness about food safety, stringent regulatory requirements, and advances in nanotechnology and sensor development. Smart packaging addresses these challenges by providing real-time information and actively maintaining optimal conditions for food products.

Types of Smart Packaging Systems

Smart packaging encompasses a diverse range of technologies, each designed to address specific challenges in food preservation and information delivery. Understanding these systems helps manufacturers select appropriate solutions for their products and integrate them with existing production processes.

Time-temperature indicators are among the most widely adopted smart packaging features. These visual indicators show whether a product has been exposed to temperature variations that could compromise quality. The indicators change color irreversibly when products experience temperature abuse, providing immediate visual confirmation of proper cold chain maintenance. This technology is particularly valuable for frozen foods, dairy products, and pharmaceuticals.

Freshness indicators detect chemical changes in food products as they deteriorate, providing consumers with reliable information about actual food quality rather than relying solely on expiration dates. These indicators respond to metabolic byproducts such as carbon dioxide, volatile nitrogen compounds, or organic acids that accumulate as food spoils.

Gas sensors and oxygen indicators help monitor the atmosphere inside modified atmosphere packaging. These sensors detect oxygen ingress or changes in gas composition that could lead to spoilage, alerting stakeholders to potential package integrity issues before products reach consumers.

Active Packaging Technologies

Active packaging systems take a proactive approach to food preservation by interacting with the product or headspace to extend shelf life and maintain quality. These technologies represent a significant advancement beyond traditional barrier packaging.

Oxygen scavengers are among the most successful active packaging technologies. These systems absorb oxygen from within sealed packages, preventing oxidative degradation that causes rancidity, color changes, and nutrient loss. Oxygen scavengers are particularly effective for products sensitive to oxidation, including baked goods, coffee, nuts, and cured meats. Modern scavenger systems can be incorporated into packaging films, labels, or sachets.

Moisture control systems regulate humidity levels inside packages through absorbers or emitters. Moisture absorbers prevent excess moisture that promotes microbial growth and textural changes, while moisture emitters maintain adequate humidity for products like fresh produce and baked goods. These systems help maintain optimal conditions throughout distribution and storage.

Antimicrobial packaging releases preservative substances that inhibit microbial growth on food surfaces. These systems can incorporate natural antimicrobials such as essential oils, organic acids, or bacteriocins into packaging materials. The controlled release of these compounds provides sustained antimicrobial protection, potentially reducing or eliminating chemical preservatives in food formulations.

Ethylene absorbers target fruits and vegetables by removing ethylene gas, which accelerates ripening and senescence. By controlling ethylene levels, these systems significantly extend the shelf life of fresh produce during transportation and retail display.

Intelligent Packaging Features

Intelligent packaging focuses on monitoring and communication rather than active intervention. These systems provide valuable information about product history, current condition, and authenticity, empowering better decision-making throughout the supply chain.

Radio-frequency identification (RFID) tags and near-field communication (NFC) chips enable digital tracking and authentication. These technologies allow manufacturers to track products throughout the supply chain, combat counterfeiting, enable interactive consumer experiences, and facilitate efficient inventory management. Consumers can scan packages with smartphones to access detailed product information, recipes, sustainability data, and authentication verification.

QR codes and data matrices provide cost-effective information delivery. While less sophisticated than RFID, these printed codes offer excellent value for providing consumers with access to digital content including traceability information, usage instructions, nutritional data, and marketing content. The widespread availability of smartphone cameras makes these codes universally accessible.

Biosensors represent cutting-edge intelligent packaging, detecting specific biological or chemical markers that indicate freshness, contamination, or authenticity. These sensors can identify pathogenic bacteria, allergens, toxins, or other substances of concern, providing unprecedented food safety assurance.

Benefits of Smart Packaging for Food

The implementation of smart packaging technology delivers substantial benefits across the entire food value chain, from production facilities to consumer homes. Understanding these advantages helps justify the investment in advanced packaging solutions.

Food waste reduction stands as perhaps the most significant benefit. Smart packaging provides accurate information about actual food quality rather than relying on conservative expiration dates. This precision reduces unnecessary disposal of safe food while preventing consumption of compromised products. Industry estimates suggest that widespread adoption of smart packaging could reduce food waste by twenty to thirty percent.

Enhanced food safety represents another critical advantage. Real-time monitoring of temperature, package integrity, and microbial activity helps identify problems before products reach consumers. This proactive approach protects public health and shields brands from costly recalls and reputation damage.

Supply chain efficiency improves dramatically with smart packaging implementation. Automated tracking reduces manual labor, provides real-time visibility into product location and condition, enables dynamic routing based on product status, and facilitates quick identification and isolation of problematic batches. These efficiencies translate into reduced logistics costs and improved operational performance.

Consumer engagement opportunities expand significantly with smart packaging. Interactive features create connections between brands and consumers, provide valuable usage information and recipes, enable loyalty programs and promotions, and build trust through transparency about sourcing and production methods.

Integration with Food Packaging Machinery

Implementing smart packaging technology requires careful integration with existing production infrastructure. Modern food packaging machinery and equipment increasingly incorporate capabilities to handle smart packaging components, but successful implementation demands strategic planning and often system modifications.

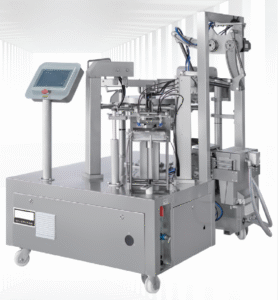

Advanced food packaging machinery and equipment now feature specialized modules for applying smart packaging elements. These systems can automatically place time-temperature indicators, print and apply QR codes, insert active packaging components, and integrate RFID tags during high-speed production runs. The key to successful implementation lies in selecting machinery that accommodates smart packaging features without significantly reducing production speeds.

Manufacturers must consider several factors when upgrading or acquiring food packaging machinery and equipment for smart packaging applications. Equipment must maintain precise placement accuracy for sensors and indicators, offer flexibility to accommodate different smart packaging formats, provide gentle handling to avoid damaging sensitive electronic components, and include verification systems to ensure proper application of all smart packaging elements.

Integration challenges often include synchronizing smart packaging application with existing production speeds, training operators on new technologies and quality control procedures, establishing protocols for testing and verifying smart packaging functionality, and managing data systems that collect and process information from intelligent packaging features.

Leading manufacturers of food packaging machinery and equipment now offer turnkey solutions that incorporate smart packaging capabilities. These integrated systems streamline implementation by providing pre-configured equipment, technical support and training, software for data management and analysis, and ongoing maintenance and upgrade services.

Real-World Applications and Examples

Smart packaging technology has moved beyond theoretical concepts to practical applications across various food sectors. These real-world implementations demonstrate the technology’s versatility and value.

In the meat and poultry industry, freshness indicators provide visual confirmation of product quality. Major retailers have adopted packaging that changes color when proteins begin deteriorating, giving consumers confidence in product freshness. Temperature indicators on frozen meat products ensure the cold chain remained intact from processing plant to home freezer.

The fresh produce sector benefits significantly from ethylene management and humidity control systems. Smart packaging for berries, leafy greens, and other delicate produce extends shelf life by days or weeks, reducing waste and improving profitability for retailers while delivering better quality to consumers.

Dairy products utilize time-temperature indicators extensively, particularly for products requiring strict cold chain maintenance. Smart packaging on yogurt, milk, and cheese provides assurance that products remained at safe temperatures throughout distribution.

Ready-to-eat meals and prepared foods employ multiple smart packaging technologies simultaneously. Active oxygen scavengers extend shelf life, freshness indicators monitor quality, and QR codes provide reheating instructions and nutritional information. This comprehensive approach addresses the unique challenges of convenience foods.

The wine and spirits industry has embraced NFC and RFID technology for authentication and consumer engagement. Smart labels enable consumers to verify authenticity, access information about vineyard origins, and participate in interactive brand experiences.

Future Trends in Smart Packaging

The smart packaging landscape continues evolving rapidly, with emerging technologies promising even greater capabilities and more widespread adoption in coming years.

Nanotechnology integration represents a major frontier. Nano-sensors can detect minute quantities of spoilage indicators, pathogens, or contaminants with unprecedented sensitivity. Nano-materials improve barrier properties while enabling new active packaging functions. Research into edible nano-sensors could eliminate the need for separate packaging components.

Internet of Things connectivity will transform smart packaging from passive indicators to active participants in connected ecosystems. Packages will communicate with refrigerators, smartphones, and supply chain management systems, providing real-time alerts, automatically updating inventory systems, suggesting recipes based on available ingredients, and triggering reordering when supplies run low.

Biodegradable and sustainable smart packaging addresses environmental concerns while maintaining advanced functionality. Researchers are developing smart packaging features using natural materials, compostable sensors and indicators, and packaging that degrades safely after use while still providing sophisticated monitoring capabilities during its functional lifetime.

Artificial intelligence and machine learning will enhance smart packaging capabilities by analyzing patterns in sensor data to predict shelf life more accurately, identifying optimal distribution routes based on product condition, detecting anomalies that indicate quality issues, and personalizing information delivery based on consumer preferences and behaviors.

Standardization and cost reduction will drive mainstream adoption. As technologies mature and production volumes increase, smart packaging costs continue declining. Industry standardization efforts aim to create interoperable systems that work across brands and retailers, making implementation more straightforward and economical.

Conclusion

Smart packaging technology for food represents a transformative innovation that addresses critical challenges in food safety, quality maintenance, waste reduction, and consumer engagement. By combining active preservation systems with intelligent monitoring and communication capabilities, smart packaging elevates food packaging from a simple container to an integral component of food quality management.

The successful implementation of smart packaging requires investment in appropriate food packaging machinery and equipment capable of integrating these advanced features into production processes. As technology continues advancing and costs decline, smart packaging is transitioning from a premium feature to an expected standard across many food categories.

For food manufacturers, processors, and packaging companies, embracing smart packaging technology offers competitive advantages through reduced waste, enhanced safety, improved supply chain efficiency, and stronger consumer connections. The integration of smart features with modern food packaging machinery and equipment creates production systems capable of meeting evolving market demands while contributing to more sustainable food systems.

As we look toward the future, smart packaging will become increasingly sophisticated, affordable, and ubiquitous. The convergence of nanotechnology, Internet of Things connectivity, and sustainable materials promises to deliver packaging solutions that are simultaneously more intelligent and more environmentally responsible. For stakeholders throughout the food value chain, understanding and adopting smart packaging technology is not merely an option but an essential strategy for success in the evolving food industry landscape.

We are a professional food packaging machine manufacturer. Contact us today to learn how our advanced equipment can integrate smart packaging technology into your production line.