Table of Contents

- Introduction

- The Importance of Proper Biscuit Packaging

- Types of Biscuit Packaging Methods

- How a Biscuit Packing Machine Works

- Key Components of Modern Biscuit Packing Machines

- Packaging Materials Used for Biscuits

- Quality Control in Biscuit Packaging

- Automated vs Manual Biscuit Packaging

- Future Trends in Biscuit Packaging Technology

- Conclusion

Introduction

Biscuit packaging is a critical step in the manufacturing process that ensures products reach consumers in perfect condition. From maintaining freshness to protecting against breakage, the packaging process involves sophisticated machinery and precise techniques. Understanding how biscuits are packaged reveals the complexity behind what seems like a simple wrapped snack on store shelves.

The Importance of Proper Biscuit Packaging

Proper packaging serves multiple essential functions in the biscuit industry. First and foremost, it preserves freshness by creating a barrier against moisture, air, and contaminants that could compromise the product’s texture and taste. Packaging also provides physical protection during transportation and handling, preventing breakage that would make biscuits unsellable.

Beyond preservation, packaging serves as a marketing tool, displaying brand information, nutritional facts, and appealing designs that attract consumers. It also ensures compliance with food safety regulations and extends shelf life, reducing waste throughout the supply chain.

Types of Biscuit Packaging Methods

Manufacturers employ various packaging methods depending on the biscuit type, market requirements, and production scale. The most common methods include:

Flow Wrapping: This popular method uses a horizontal wrapping technique where biscuits pass through a machine that wraps them in a continuous film, creating airtight seals on both ends. Flow wrapping is ideal for individually wrapped biscuits or small stacks.

Tray and Overwrap: Biscuits are first arranged in plastic or cardboard trays, then wrapped with an outer film. This method provides excellent protection and is commonly used for premium or delicate biscuits.

Pillow Pack: Similar to flow wrapping but creates a pillow-shaped package with three seals. This method is efficient for high-speed production lines.

Vertical Form Fill Seal (VFFS): A versatile method where packaging film is formed into a tube, filled with biscuits, and sealed vertically, commonly used for smaller, individually wrapped biscuits.

How a Biscuit Packing Machine Works

A modern biscuit packing machine operates through a carefully orchestrated sequence of automated steps. The process typically begins with biscuits arriving from the cooling conveyor after baking. These biscuits are first organized and oriented correctly using feeding systems that may include vibratory feeders or belt conveyors.

The machine then groups biscuits into predetermined quantities using counting mechanisms or weight-based systems. Once grouped, the biscuits move to the wrapping station where packaging film is drawn from large rolls. The film passes through forming stations that shape it around the product.

Sealing bars heated to precise temperatures create airtight seals through heat and pressure. Modern machines use servo motors for accurate positioning and can achieve speeds of 200 to 400 packages per minute, depending on the model and product specifications. Throughout this process, sensors monitor positioning, ensuring consistent package quality.

Key Components of Modern Biscuit Packing Machines

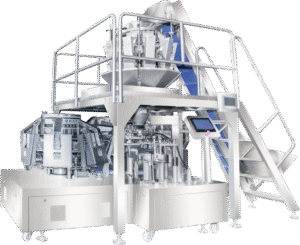

A sophisticated biscuit packing machine comprises several integrated components working in harmony:

Feeding System: Conveyors and guides that transport biscuits from production lines and orient them correctly for packaging.

Film Handling System: Includes film rollers, tension controllers, and registration systems that manage packaging material smoothly and accurately.

Forming Stations: Mechanical components that shape flat film around the product, often using forming boxes or collars.

Sealing Mechanisms: Heated jaws or bars that create longitudinal and end seals, with temperature controls ensuring optimal seal strength without damaging packaging.

Cutting System: Rotary or reciprocating knives that separate individual packages from continuous film.

Control Panel: User-friendly interfaces, often touchscreen-based, allowing operators to adjust parameters like speed, temperature, and package dimensions.

Reject System: Automated mechanisms that detect and remove improperly sealed or damaged packages.

Packaging Materials Used for Biscuits

The choice of packaging material significantly impacts product protection and shelf life. Common materials include:

Polypropylene (PP): Offers excellent moisture barrier properties and is widely used for flow-wrapped biscuits. It’s cost-effective and provides good transparency for product visibility.

Polyethylene (PE): Often used in multi-layer laminates, PE provides good sealing properties and flexibility.

Metallized Films: Incorporating a thin aluminum layer, these films provide superior barrier protection against light, oxygen, and moisture, ideal for premium biscuits requiring extended shelf life.

Paper-based Laminates: Increasingly popular for sustainability, these materials combine paper with thin plastic layers, offering environmental benefits while maintaining protective qualities.

Multi-layer Laminates: Combining different materials, these sophisticated films optimize multiple properties like strength, barrier performance, and printability.

Quality Control in Biscuit Packaging

Maintaining consistent package quality requires comprehensive quality control measures throughout the packaging process. Modern biscuit packing machines incorporate various inspection systems including vision systems that use cameras to verify seal integrity, check for proper product orientation, and ensure labeling accuracy.

Metal detectors screen packages for any contaminating foreign objects, while weight checkers ensure each package contains the correct product quantity. Seal testers periodically verify that packages are airtight, and operators conduct regular visual inspections to catch issues automated systems might miss.

Documentation systems track production data, creating traceable records for regulatory compliance and quality assurance purposes.

Automated vs Manual Biscuit Packaging

The contrast between automated and manual packaging is stark in terms of efficiency and consistency. Manual packaging, while requiring minimal capital investment, is labor-intensive, slower, and prone to inconsistency. It may suit small-scale artisanal operations or specialty products with low volumes.

Automated biscuit packing machines, conversely, offer numerous advantages. They dramatically increase production speed, handling hundreds of packages per minute compared to manual operations. Consistency improves as machines maintain uniform package quality and weight. Long-term labor costs decrease despite higher initial investment, and automated systems better meet food safety standards by minimizing human contact with products.

Modern machines also offer flexibility, with quick changeover capabilities allowing manufacturers to package different biscuit varieties or sizes on the same line with minimal downtime.

Future Trends in Biscuit Packaging Technology

The biscuit packaging industry continues evolving, driven by technological advancement and changing consumer expectations. Several trends are shaping the future:

Sustainability Focus: Manufacturers increasingly adopt biodegradable, compostable, and recyclable materials. Machines are being designed to handle these new sustainable materials efficiently.

Smart Packaging: Integration of QR codes, NFC chips, and freshness indicators that provide consumers with product information and supply chain transparency.

Industry 4.0 Integration: Connected machines sharing real-time data, predictive maintenance capabilities, and remote monitoring optimize production efficiency.

Enhanced Flexibility: Machines capable of handling wider product ranges and package formats without extensive reconfiguration.

Improved Energy Efficiency: New designs focusing on reducing energy consumption through optimized heating systems and more efficient motors.

Conclusion

The packaging of biscuits is a sophisticated process combining engineering precision, material science, and quality control. Modern biscuit packing machines represent significant technological achievements, delivering speed, consistency, and reliability that manual processes cannot match. As consumer demands evolve and sustainability becomes paramount, packaging technology continues advancing, ensuring biscuits reach consumers in optimal condition while minimizing environmental impact.

Are you looking for reliable packaging solutions? We are a professional biscuit packing machine equipment manufacturer, dedicated to providing cutting-edge packaging technology that meets your production needs. With our state-of-the-art machinery and comprehensive technical support, we help businesses optimize their packaging operations for maximum efficiency and product quality. Contact us today to discover how our biscuit packing machines can transform your production line.