What is a Powder Packing Machine?

Table of Contents

Introduction

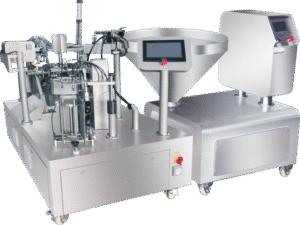

In today’s fast-paced manufacturing and packaging industry, efficiency and precision are paramount. Powder packing machines have emerged as essential equipment for businesses dealing with powdered products, from food ingredients to pharmaceuticals. These automated systems revolutionize the way powdered materials are packaged, ensuring consistency, speed, and hygiene throughout the packaging process. Understanding what a powder packing machine is and how it operates can help businesses make informed decisions about their packaging needs.

Definition and Basic Concept

A powder packing machine is an automated packaging equipment designed specifically to measure, fill, and seal powdered products into various types of containers or pouches. These machines handle fine, granular, or powdered substances with precision, eliminating the inconsistencies and contamination risks associated with manual packaging. The primary function of a powder packing machine is to streamline the packaging process while maintaining product quality and reducing labor costs.

These machines are engineered to handle the unique challenges that powdered materials present, such as dust generation, product flow characteristics, and the need for accurate dosing. Modern powder packing machines incorporate advanced technology to ensure that each package contains the exact amount of product specified, maintaining brand reputation and regulatory compliance.

How Does a Powder Packing Machine Work?

The operation of a powder packing machine typically follows a systematic process that ensures efficient and accurate packaging. First, the powder is stored in a hopper or container at the top of the machine. From there, the powder is measured using various dosing systems such as auger fillers, volumetric cups, or weighing scales, depending on the machine type and accuracy requirements.

Once the correct amount is measured, the powder is dispensed into pre-formed bags, pouches, or containers through filling tubes or nozzles designed to minimize dust and spillage. The packaging material is then sealed using heat sealing, ultrasonic sealing, or other appropriate methods depending on the material type. Throughout this process, the machine may include features such as dust extraction systems, anti-static devices, and cleaning mechanisms to maintain hygiene and product integrity.

Many modern powder packing machines operate continuously with minimal human intervention, automatically forming bags from roll film, filling them, sealing them, and even printing batch codes or expiration dates on the packages.

Types of Powder Packing Machines

There are several types of powder packing machines available, each designed for specific applications and production requirements:

Auger Filling Machines: These machines use a rotating auger screw to measure and dispense powder. They are ideal for fine, free-flowing powders and offer high accuracy. Auger fillers are commonly used in the pharmaceutical and food industries.

Volumetric Filling Machines: These machines measure powder by volume rather than weight. They are faster than auger fillers but may be less accurate, making them suitable for applications where slight variations are acceptable.

Net Weight Filling Machines: These systems use electronic scales to ensure precise weight measurements. They are perfect for applications requiring high accuracy and are commonly used for expensive or regulated products.

Vertical Form Fill Seal (VFFS) Machines: These all-in-one machines create bags from roll film, fill them with powder, and seal them in a continuous vertical process. They are highly efficient for high-volume production.

Sachet Packing Machines: Designed specifically for producing small sachets or stick packs, these machines are popular in the food and pharmaceutical industries for single-serving portions.

Key Components and Features

Understanding the key components of a powder packing machine helps in appreciating its functionality and maintenance requirements. The hopper serves as the storage reservoir for the powder before packaging, often equipped with level sensors and agitators to ensure consistent flow.

The dosing system is arguably the most critical component, responsible for measuring the exact amount of powder for each package. This can be an auger mechanism, a volumetric cup, or a computerized weighing system. The filling nozzle or spout directs the powder into the package while minimizing dust and spillage.

The sealing unit creates airtight seals to preserve product freshness and prevent contamination. Modern machines often include temperature control for optimal seal quality. Control systems, typically featuring touchscreen interfaces and programmable logic controllers (PLCs), allow operators to adjust parameters such as fill weight, bag size, and production speed.

Additional features may include nitrogen flushing for oxygen-sensitive products, date coding systems for traceability, and metal detectors or checkweighers for quality control.

Applications and Industries

Powder packing machines serve a wide range of industries, each with unique requirements and standards. In the food industry, these machines package products such as flour, sugar, spices, coffee, protein powders, infant formula, and baking mixes. The machines must comply with food safety regulations and maintain strict hygiene standards.

The pharmaceutical industry relies heavily on powder packing machines for packaging medications, supplements, and active pharmaceutical ingredients (APIs). These applications demand the highest levels of accuracy, cleanliness, and regulatory compliance, often requiring machines made from stainless steel with validation documentation.

In the chemical industry, powder packing machines handle detergents, fertilizers, industrial chemicals, and pesticides. These machines must be robust enough to handle potentially corrosive or hazardous materials safely. The cosmetics industry uses these machines for face powders, bath salts, and other powdered beauty products, where presentation and consistency are crucial.

Other applications include construction materials like cement additives, agricultural products, and nutritional supplements for both human and animal consumption.

Benefits of Using Powder Packing Machines

Implementing powder packing machines in production lines offers numerous advantages that justify the investment. Increased efficiency is perhaps the most immediate benefit, as automated machines can package hundreds or thousands of units per hour, far exceeding manual capabilities and allowing businesses to meet high-volume demands.

Consistency and accuracy ensure that every package contains the precise amount of product, reducing waste, maintaining customer satisfaction, and ensuring compliance with regulations. This accuracy also protects profit margins by preventing overfilling.

Improved hygiene and reduced contamination are critical benefits, especially in food and pharmaceutical applications. Automated systems minimize human contact with products, reducing contamination risks and ensuring compliance with strict hygiene standards.

Labor cost reduction is significant, as machines require fewer operators than manual packaging lines. This allows businesses to reallocate human resources to higher-value tasks while reducing long-term operational costs.

Enhanced product protection through consistent sealing quality helps extend shelf life and maintain product integrity during storage and transportation. Additionally, modern machines offer flexibility to handle different package sizes and formats, enabling businesses to adapt to market demands quickly.

Choosing the Right Powder Packing Machine

Selecting the appropriate powder packing machine requires careful consideration of several factors. First, evaluate the characteristics of your powder, including particle size, flow properties, density, and any special handling requirements. Free-flowing powders may work well with volumetric fillers, while sticky or fine powders might require auger systems.

Production capacity needs should match the machine’s output capabilities. Consider both current requirements and future growth to ensure the machine can scale with your business. Package type and size preferences will also influence your choice, as different machines accommodate various formats from small sachets to large bags.

Accuracy requirements vary by industry and product. Pharmaceutical and high-value products typically demand net weight filling systems, while food products might use volumetric systems for cost efficiency. Budget considerations should account not only for initial purchase price but also installation, training, maintenance, and operational costs.

Space availability in your facility will determine whether you need a compact machine or can accommodate larger, higher-capacity equipment. Finally, ensure that any machine you consider meets relevant industry regulations and standards, particularly for food safety or pharmaceutical manufacturing.

Conclusion

Powder packing machines represent a crucial investment for businesses handling powdered products across various industries. These sophisticated systems combine precision, efficiency, and hygiene to deliver consistent packaging results that meet modern quality standards and consumer expectations. By understanding the different types of machines, their components, and applications, businesses can select equipment that optimizes their production processes and supports long-term growth.

As technology continues to advance, powder packing machines are becoming increasingly intelligent, featuring improved automation, connectivity, and data analytics capabilities. Whether you’re packaging food products, pharmaceuticals, or industrial chemicals, the right powder packing machine can significantly enhance your operational efficiency, product quality, and bottom line.

Partner With Industry Experts

We are professional powder packing machine equipment manufacturers, dedicated to providing high-quality, reliable packaging solutions tailored to your specific needs. Contact us today to discover how our advanced powder packing machines can transform your production line and drive your business forward.